Global Mine High-Strength Steel Strand Lock – Single/Multi-Hole Support for Deep Mines | Jiufu

Core Product Characteristics

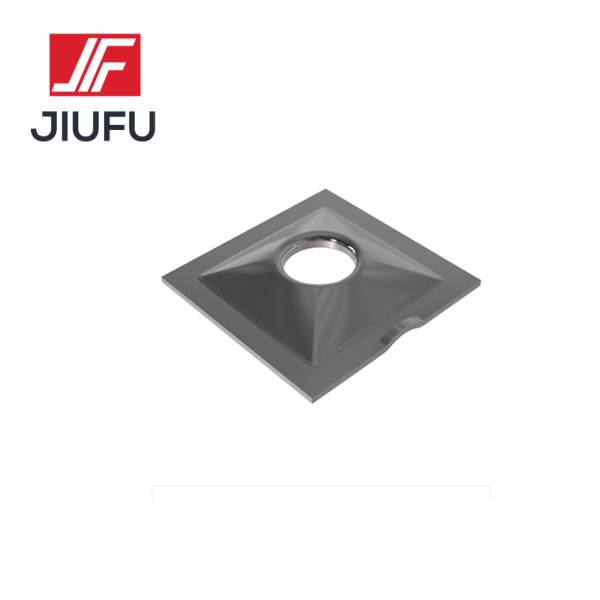

1. Premium Material & Precision Craftsmanship

2. Heavy-Duty Performance & Customizable Load Capacity

3. Global Compliance & Corrosion Resistance

4. Easy Installation & Universal Adaptability

| Core Parameters | Standard Specifications | Customization Options | Global compatibility standards | Performance Specifications |

| Number of holes/slots | Single hole (1-2 strands), Multi-hole (3-6 strands) | Single-strand (1-4 strands), Multi-strand (3-8 strands) | ISO 898-1, ASTM A325, CE | Load Capacity: 150-500 KN |

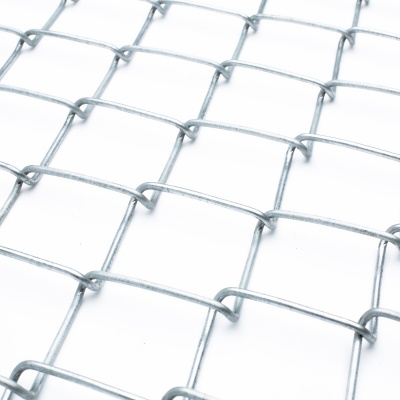

| Compatible steel strand diameter | 15.24mm, 17.8mm | 12.7mm-19.5mm | Australian AS and South African SANS | Pull-out Resistance: ≥1.2 × Rated Load |

| Lock body material | 40Cr/45# Alloy Steel | Custom high-strength alloy steel | Russian GOST and Vietnamese TCVN standards | Yield Strength: ≥800 MPa |

| Surface treatment | Hot-dip galvanized (430g/㎡) | Hot-dip galvanized (430-600g/㎡), Epoxy coating | Corrosion resistance rating: C5-M (ISO 12944) | Fatigue Life: ≥10^6 cycles |

| Dimensions (diameter × height) | 80×50mm (single hole), 120×80mm (multi-hole) | 60×40mm~150×100mm | --- | Operating Temperature: -40℃~80℃ |

Global Application Scenarios

1. Deep Mining Support

2. Large-Scale Tunnel Engineering

3. Mine Shaft & Hydropower Projects

Key Advantages

Customization Service

Global Shipping & After-Sales Support

Quality Control

Write your message here and send it to us