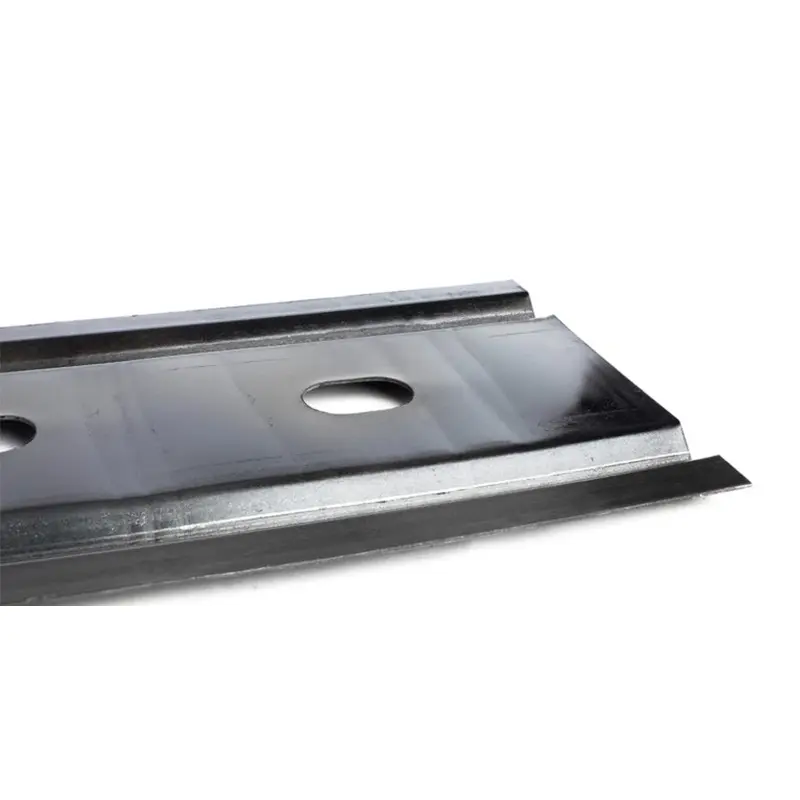

Crafted from PSB1080 high-strength fine-rolled ribbed steel (yield strength ≥1080 Mpa, ultimate tensile strength ≥1230 Mpa), the anti-floating anchor features a full-thread structure for seamless connection and deep anchoring (5-30m customizable). Key design highlights:

- Full-thread design: Ensures stable connection with couplers, allowing flexible extension of anchoring depth without strength loss.

- High uplift capacity: 100-500 KN customizable anti-floating load, 40% higher than standard anchors—effectively resisting structural uplift from groundwater pressure.

- Corrosion resistance: Multiple surface treatment options to adapt to harsh environments:

- Hot-dip galvanizing (430-600g/㎡): Ideal for humid basements and inland projects (complies with ISO 12944 C4 standard).

- Epoxy coating: Superior protection against salt spray, acidic/alkaline soil—perfect for coastal and coastal projects (meets C5-M corrosion standard).

- Grout compatibility: Works with cement grout, chemical grout, and polymer grout, forming a solid bond with rock/soil to enhance load transfer.

The product is ISO9001 certified and complies with international standards including GB/T 20065 (China), ASTM A722 (North America), EU CE (Europe), Australian AS 10125, and Russian GOST 25900. This ensures seamless integration into cross-border projects, avoiding rework due to standard mismatches.

Our anti-floating anchors are tailored to diverse geological and project types worldwide, solving region-specific uplift challenges:

- Regions: Europe (London, Berlin), North America (New York, Toronto), China (Shanghai, Shenzhen)

- Application: 50+ story high-rises, underground shopping malls, subway stations

- Solution: PSB1080/PSB1200 grade anchors (32-40mm diameter, 15-25m depth) with 300-500 KN load capacity—resist uplift from high groundwater in urban core areas.

- Regions: Southeast Asia (Vietnam, Indonesia), Australia (Sydney, Brisbane), Mediterranean Coast

- Application: Coastal ports, waterfront residential buildings, offshore platforms

- Solution: Epoxy-coated anchors (25-32mm diameter, 15-20m depth) with anti-corrosion grout—adapt to soft soil and salt spray erosion, service life ≥25 years.

- Regions: Brazil (Amazon Basin), India (Ganges Basin), Southeast Asia (Mekong River)

- Application: Dams, irrigation facilities, reservoir banks

- Solution: Hot-dip galvanized anchors (32-40mm diameter, 20-30m depth) with cement grout—withstand long-term water pressure and humid environments.

- Regions: Siberia (Russia), Northern Canada, Middle East (Gulf Countries)

- Application: Arctic infrastructure, desert oasis projects

- Solution: Low-temperature resistant PSB1080 anchors (25-32mm diameter, 10-15m depth) with anti-freezing grout—stable performance in -40℃ to 60℃ environments.

- PSB1080 high-strength steel core + pressure grouting (2.5-4 MPa) forms a "steel-grout-rock/soil" integrated system, ensuring uniform load transfer and 100-500 KN anti-floating capacity.

- Deep anchoring design (up to 30m) penetrates unstable shallow soil layers, anchoring into stable rock/soil for long-term reliability.

- Full-thread connection allows quick assembly without welding, reducing construction time by 30% compared to traditional anchors.

- Lightweight design (per meter weight ≤20kg) simplifies transportation and on-site handling, lowering labor costs.

- Customizable load, diameter, and depth to match project-specific uplift force and geological conditions.

- Corrosion-resistant surface treatments and high-quality steel material ensure service life ≥25 years, reducing maintenance and replacement costs.

- Tools Required: Core drill (25-50mm bit), high-pressure grouting pump (≥2.5 MPa), torque wrench (≥200 N·m), depth measuring tape, compressed air device (≥0.6 MPa), grout mixer, water pump (for high groundwater regions).

- Material Preparation: High-strength anti-floating anchors, couplers (for extended depth), grout (cement/chemical/anti-corrosion type), centralizers, and water-stopping rings.

- On-Site Check: Conduct geological survey to confirm groundwater level, soil/rock type, and uplift force; mark drilling positions (spacing: 1.5-3m, hole diameter 10-15mm larger than anchor diameter).

- Drilling: Drill vertical holes (angle deviation ≤5°) to the designed depth. Use diamond-tipped bits for hard rock (Europe/North America) and spiral bits for soft soil (Southeast Asia).

- Hole Cleaning: Blow holes repeatedly with compressed air from bottom to top to remove dust and loose particles. For high groundwater regions, use a water pump to drain water before cleaning.

- Anchor Insertion: Insert the anti-floating anchor into the hole, using centralizers to keep it centered (ensures uniform grout coverage). Connect multiple anchors with couplers if extended depth is required.

- Pressure Grouting: Inject grout from bottom to top at 2.5-4 MPa pressure—avoid voids. For coastal projects, add anti-corrosion admixtures to the grout; for permafrost regions, use low-temperature resistant grout.

- Curing: Allow grout to cure for 7-14 days (20-25℃); extend to 21 days in humid or low-temperature environments.

- Load Testing: Use a hydraulic jack to verify uplift resistance (≥1.2× designed load). Mark qualified anchors for project acceptance.

- Coastal Soft Soil Regions (Southeast Asia/Australia): Use epoxy-coated anchors and anti-corrosion grout; increase anchoring depth by 30% to penetrate stable soil layers; avoid drilling during high tide to prevent hole collapse.

- High Groundwater Regions (Middle East/Europe): Drain groundwater before drilling; install water-stopping rings at the anchor top to prevent water seepage into the foundation; use chemical grout for better adhesion in water-rich strata.

- Hard Rock Regions (North America/Canada): Use diamond-tipped drills for deep, precise holes; pre-grout fractured rock to seal gaps—ensures uniform load transfer and avoids local stress concentration.

- Permafrost Regions (Siberia): Pre-heat drill holes to 5-10℃ with a portable heater; use anti-freezing grout and low-temperature resistant steel anchors; complete installation within 12 hours to prevent re-freezing.

We understand that every anti-floating project has unique requirements—our tailored solutions ensure perfect alignment with your needs:

- Anti-floating load: 100-500 KN (customizable to higher values for special projects).

- Anchor specifications: Diameter (20-50mm), length (5-30m), thread type (metric/imperial UNC/UNF).

- Material grade: PSB930 (yield ≥930 Mpa), PSB1080 (standard), PSB1200 (yield ≥1200 Mpa).

- Surface treatment: Hot-dip galvanizing (430-600g/㎡), epoxy coating (0.8-1.2mm thickness).

- Grout type: Cement grout, chemical grout, anti-corrosion grout, low-temperature grout.

- Provide project details: Structural uplift force, geological report (soil/rock type, groundwater level), and design requirements.

- Our engineers develop a customized anti-floating solution (anchor size, depth, material, grout type) within 24 hours.

- Confirm sample (free for orders over 1000pcs) for performance testing and verification.

- Mass production with strict quality control (ISO9001 certified).

- Global delivery with tracking, plus on-site technical support if needed.

- Ports & Terms: Support FOB (Tianjin Port), CIF, CFR, DDU, and DDP.

- Delivery Time: 7-30 days to 150+ countries (Europe: 12 days, Africa: 18 days, Southeast Asia: 10 days, North America: 15 days).

- Packaging: Anti-corrosion, shockproof packaging (waterproof film + corrugated cartons + pallets) to protect anchors during long-distance shipping.

Accept TT, L/C, Trade Assurance, Credit Card, and Western Union—flexible options for global clients.

- 24/7 technical support via WhatsApp/email (multilingual: English, Spanish, Russian, Vietnamese).

- Warranty: Free replacement for defective products within 1 year (covers material and craftsmanship issues).

- On-site support: Installation guidance and team training for orders over 5000pcs.

- Lifetime consultation: Expert advice on anti-floating design optimization and performance maintenance.

Jiufu adheres to a strict quality management system, with comprehensive inspections tailored to anti-floating anchor performance:

- Raw Material Inspection: Chemical composition and mechanical performance testing for PSB1080 steel (yield strength ≥1080 Mpa, elongation ≥10%).

- Production Process Control: Thread precision measurement (tolerance ±0.02mm), heat treatment temperature monitoring (950-1050℃), and surface treatment thickness verification.

- Finished Product Testing:

- Uplift resistance test (≥1.2× designed load).

- Corrosion resistance test (salt spray ≥800 hours for epoxy-coated anchors).

- Grout adhesion test (≥3.5 MPa bond strength with rock/soil).

- Packaging Inspection: Waterproof and shockproof verification to ensure product integrity during shipping.

-

- Southeast Asian Coastal Mall: Supplied 3000pcs 32mm epoxy-coated anti-floating anchors (20m depth) for a waterfront shopping center. Withstood 350 KN uplift force, no structural floating reported in 5 years of operation.

- European High-Rise Basement: Delivered 2000pcs PSB1200 anti-floating anchors (15m depth) for a 50-story office building in Berlin. Passed EU CE load testing with 500 KN uplift resistance, complying with local construction standards.

- Australian Port Wharf: Provided 1500pcs anti-corrosion anti-floating anchors for a coastal wharf foundation. Adapted to salt spray and soft soil conditions, service life exceeded 10 years with no corrosion or performance decline.

- Russian Permafrost Project: Supplied 1200pcs low-temperature resistant anchors (-40℃ rated) for an Arctic infrastructure project. Stable operation in extreme cold, with uplift resistance maintained at 250 KN.

With annual sales of 50 million US dollars and 12,000 tons of products exported globally, Jiufu combines decades of anti-floating engineering expertise with a customer-centric approach. Our anchors stand out for:

- Targeted anti-floating performance: Solves uplift challenges in high groundwater, coastal, and soft soil environments.

- Global compliance: Meets regional standards worldwide, avoiding cross-border project delays.

- Customization capability: Tailored solutions for unique geological and structural needs.

- Reliable support: 24/7 global service and on-site guidance for seamless project execution.

Whether you’re building a coastal development, high-rise basement, or hydropower project, Jiufu’s high-strength anti-floating anchor delivers the uplift resistance and reliability you need. Contact us today to request a sample, get a customized quote, or discuss your project’s specific requirements—let Jiufu be your trusted