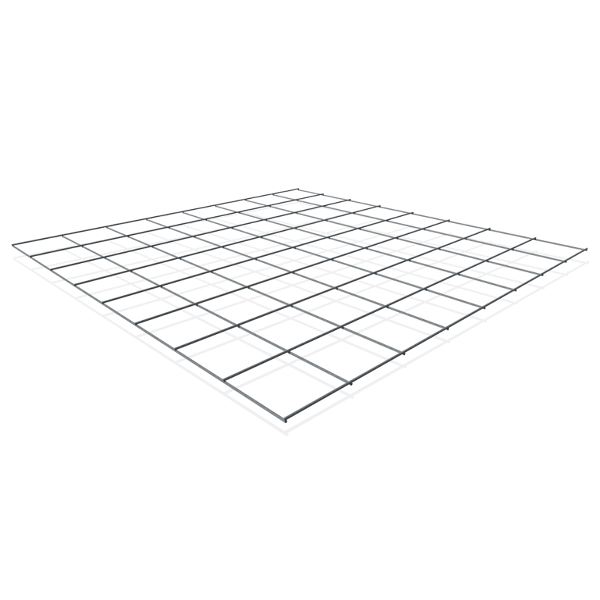

Wire Mesh for Concrete (Heavy Duty Galvanized)

Product Description

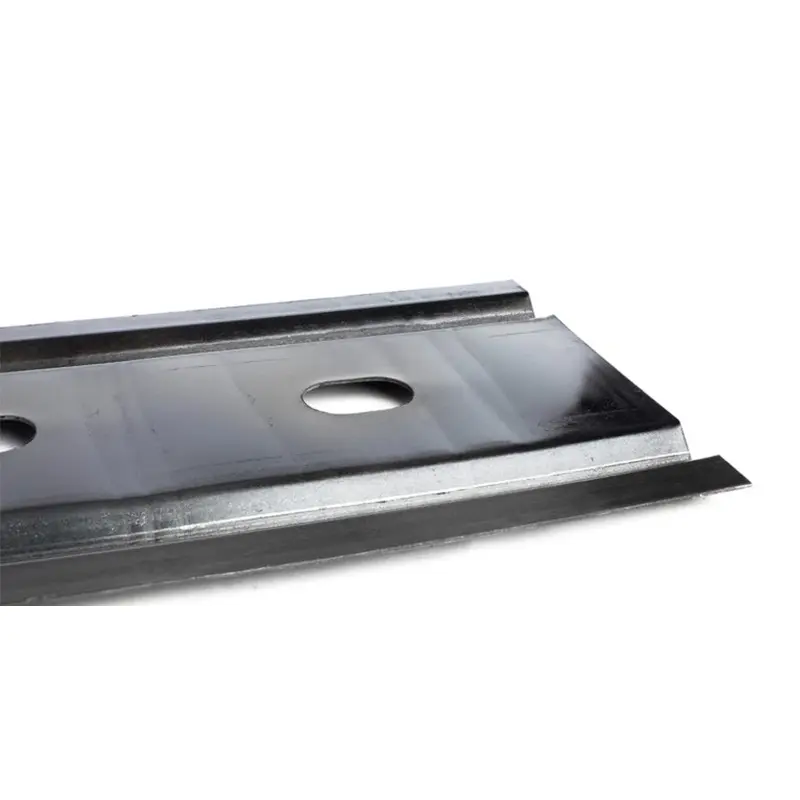

Our mining welded mesh is a critical component in modern ground support systems, designed to prevent rock fragmentation and ensure workplace safety in underground mines, tunnels, and slope stabilization projects. Manufactured from high-tensile steel wire through precision resistance welding, this mesh offers consistent strength, easy installation, and long-term durability in harsh mining environments. It is commonly used alongside rock bolts, shotcrete, and steel sets to create a reinforced barrier against rockfall and ground movement.

| Parameter Items | Surface treatment | Description |

| Wire Diameter | 3.0 mm, 3.5 mm, 4.0 mm, 5.0 mm, 6.0 mm. | Also known as "wire gauge". The larger the diameter, the greater the strength and weight of the mesh. 4.0 mm and 5.0 mm are the most commonly used. |

| Mesh size | Square holes: 50×50 mm, 80×80 mm, 100×100 mm Rectangular holes: 80×100 mm Diamond holes: 40×40 mm, 50×50 mm, 60×60 mm | This refers to the distance between the center lines of adjacent steel wires. 100×100mm and 80×80mm are the most commonly used sizes in downhole drilling. The smaller the mesh size, the better the protection, but the higher the cost and weight. |

| Mesh size | Standard Width: 0.8 m, 1.0 m, 1.2 m Standard Length: 2.0 m, 2.4 m, 3.0 m, 6.0 m | Custom sizes are available to match tunnel cross-section dimensions. Width is typically matched to anchor bolt spacing. |

| Surface treatment | Galvanized, powder coated (epoxy resin coating), black wire (untreated) | Galvanizing and powder coating effectively prevent corrosion and extend service life in damp mines. Black wire mesh is the lowest cost option. |

Our Advantages

As a specialist manufacturer of metal anchoring systems, Jiufu secures infrastructures across 150+ countries, including

Russia,South Africa, Australia, and the United States.Trusted Worldwide: From Siberian permafrost to South African deep-level mines, from Australia’s corrosive sites to North America’shard rock formations — Jiufu delivers locally-optimized performance with globally certified quality, earning consistent acclaimfrom industry leaders.

Product Features:

1.High Strength and Durability – Manufactured from high-carbon steel with resistance welding ensuring strong connections at every node, providing impact resistance and deformation resistance, suitable for high-stress rock strata conditions.

2.Active Protection and Rock Strata Control – Used in conjunction with rock bolts and shotcrete, effectively restraining loose rock and preventing detachment, improving overall tunnel stability.

3.Fast Installation and Construction Efficiency – Standardized panel or roll design, easy to transport, cut, and lay, significantly reducing support work time.

4.Excellent Corrosion Resistance – Hot-dip galvanized or PVC coating options significantly extend service life in humid and acidic mine environments, reducing maintenance costs.

5.Flexible Adaptability – Supports customized mesh size, wire diameter, and dimensions, suitable for various tunnel cross-sections, slope reinforcement, and temporary support applications.

Applications of welded wire mesh

1.Roof and side support for coal mines, metal mines, and tunnel engineering

2.Combined support system used in conjunction with split-set rock bolts and threaded steel rock bolts

3.Slope reinforcement, surface protection of underground chambers and large excavation faces

4.Temporary roadway protection, safety isolation nets, and mine infrastructure maintenance

Why choose our welded mesh?

We provide mining welded mesh that meets international safety standards and undergoes rigorous quality control. Every batch of our products is guaranteed to have uniform welding, a flat surface, and strong edges, ensuring reliable protection when it matters most. We support customized production and bulk supply, and provide professional technical selection guidance to safeguard your mine's safety and efficient production.