Split rock friction anchor

Product Description

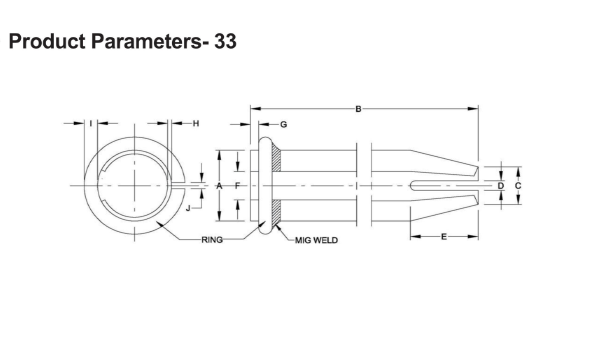

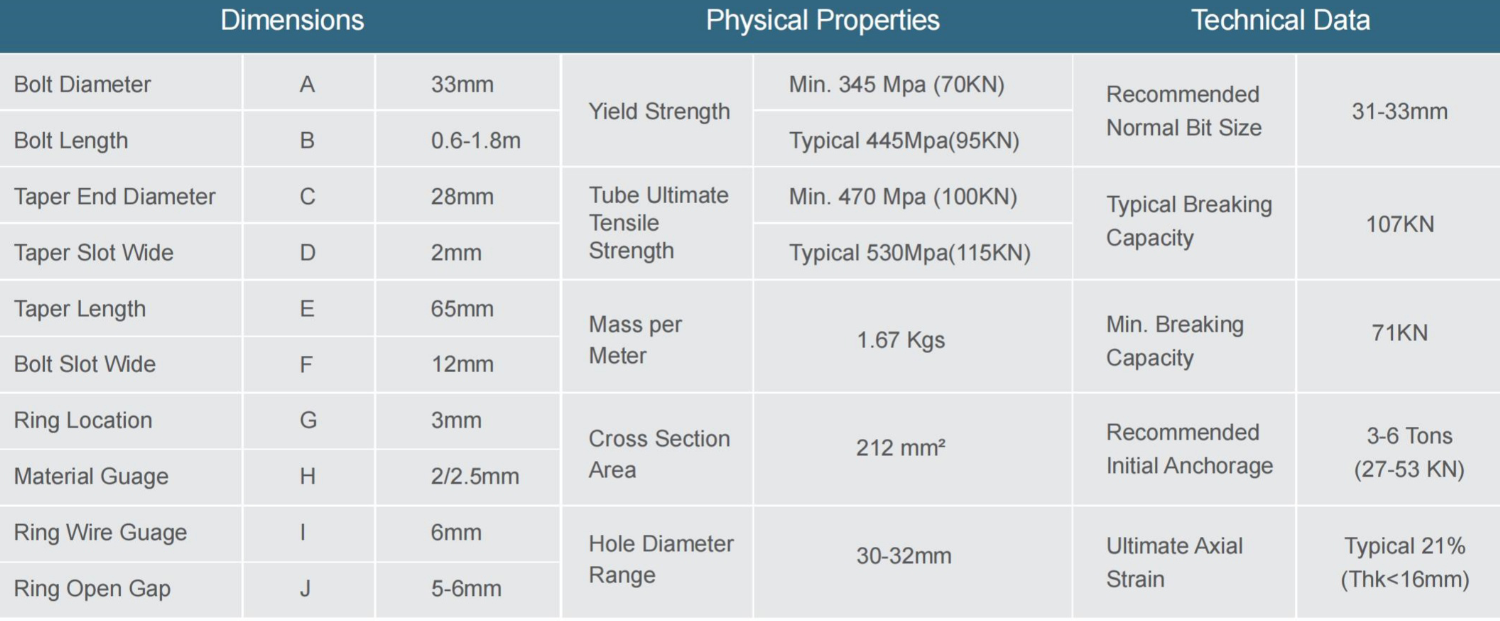

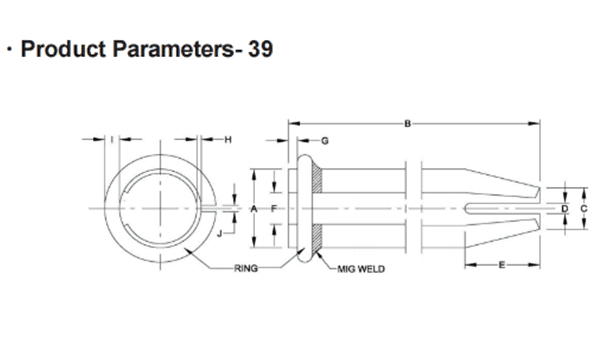

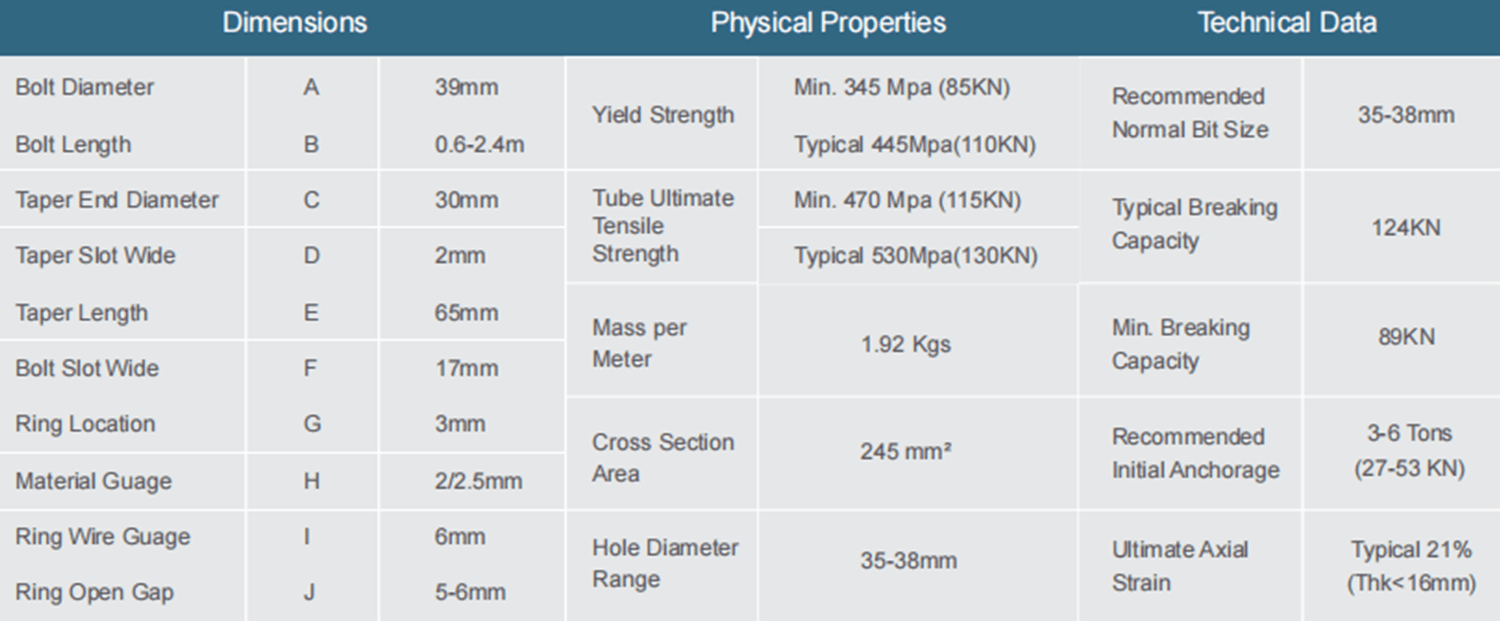

Split rock friction anchor system is also a split anchor system, which is composed of high-strength steel pipe (alloy steel strip) or thin steel plate and a perforated tray. From the appearance, it can be seen at the end of the anchor rod. A U-shaped cross-section and longitudinally grooved bolt. It is mainly used for support engineering projects and can be used in underground copper mines, recent mining, tunnel construction, bridges, dams and other infrastructure projects. In addition to the above areas, it can also be used to stabilize the ground and prevent erosion. The installation method of friction bolts is simple and the difficulty coefficient is low. It is an important advanced material in the field of engineering support projects today.

| Product Name | Diameter | Wall Thickness | Length | Surface Treatment |

| Split Set Rock Bolt |

33mm/39mm/40mm/43mm/47mm (conventional) |

1mm-4mm(conventional) |

1M-3M (conventional) |

hot dip galvanized |

| Split Set Rock Bolt | Customization | Customization | Customization | hot dip galvanized |

Product Installation

Installation method:

1.Drill holes according to specifications: Use a rock drill to drill holes in the ceiling or walls. The diameter of the hole will be slightly smaller than the diameter of the bolt.

2.Pay attention to keeping clean: Compressed air is recommended to clean the holes and remove dust and loose particles.

3.Insert the bolts: Insert the split friction bolt into the hole that exactly lines up with it, making sure the tray is resting on the surface of the ceiling or wall.

4.Installation: Place the installation tool on the bolt head and tap with a hammer until the bolt is fully installed. Tool and hammer strikes must be perfectly aligned with the bolt axis to avoid distortion. The bolt head deforms slightly to make contact with the ceiling or wall surface, creating friction that helps maintain stability.

5.Verification check: Verify bolt installation to ensure it is placed correctly and has the proper tension.

Product Advantages

1.Made of high-strength steel pipe, it is a new type of anchor.

2.Optional galvanized and stainless steel materials.

3.Suitable for mining support and other fields to improve rock stability and safety.

4.Versatility: Whether it is mining, tunneling or other underground projects, friction anchors can adapt to various complex geological conditions.

5.Easy installation: The installation process is simple, saving time and labor costs as well as the cost of composite materials. Simplicity of installation ensures efficiency without compromising performance. Friction bolts are therefore a cost-effective option.

6.Immediate load-carrying capacity: Friction bolts provide immediate load-carrying capacity after installation due to the friction generated between the bolt and the surrounding rock.

7.Reduced risk of accidents: Friction bolts are less likely to cause accidents because they don’t need to be hammered into place. This reduces the risk of rock fracture and reduces worker exposure to vibration and dust.

8.No need for anchoring agent.

1. How to start an OEM order?

Send drawings or sample-Getting price-Payment-Make mold-Confirm sample-Mass production-Payment-Delivery.

2. What is your terms of payment?

We accept TT, L/C, Trade Assurance, Credit card, Western Union etc.

3. Could you customize the packing?

The logo, carton ans pallet can be customized.

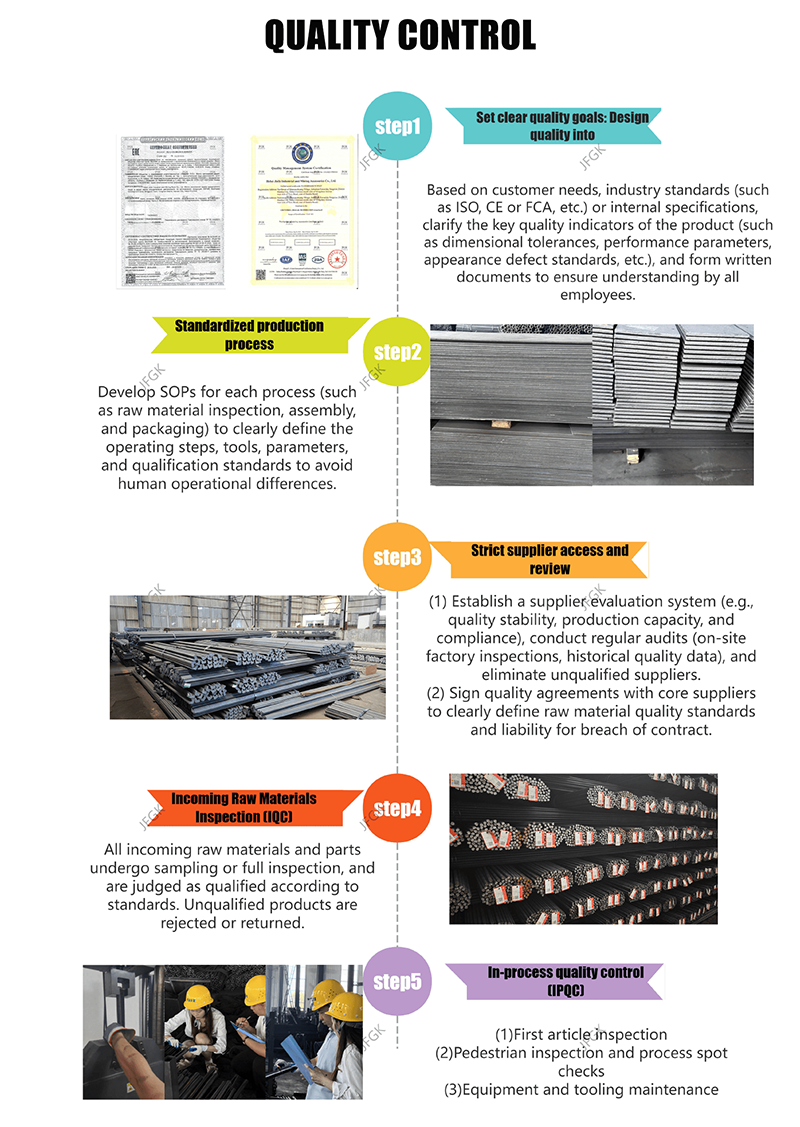

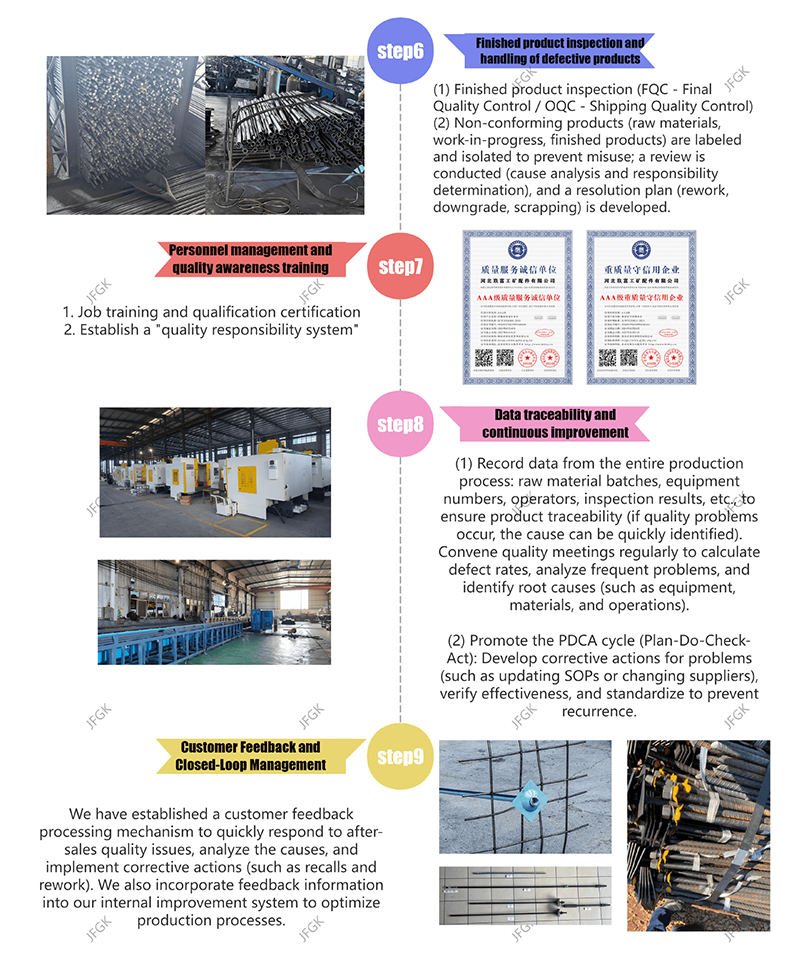

4. How do you ensure product quality?

Better control from raw material, production, processing packing, storage until to shipment.And we passed the IS09001 quality management system certification.

5.What kind of payment term you use to ship the goods?

We support FOB, CIF, CFR, DDU, DDP etc, we got very rich experience shipping goods directly to customers plant.

6.After-sales.

Quick response day and night.