Rock Mining – Long-Lasting Resin Anchor

Mining Resin Anchor: A Solid Guarantee for Mine Support

Ensuring operational safety and stability is paramount in underground mining and other projects. Mining resin anchors are core materials in this critical area, providing reliable support for various support structures.

Product Introduction

Mining resin anchors are a viscous anchoring adhesive material composed of unsaturated polyester resin, a curing agent, an accelerator, and other auxiliary materials, carefully formulated in specific proportions. A polyester film separates the cement and curing agent, and the product is packaged in rolls. This unique design and formula makes it irreplaceable in mine support.

Product Specifications

• Diameter: Available in a variety of sizes, including ¢21mm, ¢23mm, ¢28mm, ¢32mm, ¢35mm, ¢42mm, and ¢70mm, to meet different drilling diameter requirements.

• Length: Available in 300mm, 330mm, 350mm, 450mm, 500mm, 600mm, 660mm, 750mm, and 880mm lengths. Customization is also available to meet specific user requirements, ensuring a precise match to the specific needs of various projects.

Performance Parameters

• Gel Time: Available in Ultra-Fast (CKa, 8-25s, yellow marking), Fast (K, 41-90s, blue marking), and Medium (Z, 91-180s, white marking), allowing for convenient selection of the appropriate anchor based on construction schedule and process.

• Compressive Strength: At an ambient temperature of (22±1)°C and a 24-hour age, the anchor compressive strength must be no less than 60MPa, ensuring the stability of the support structure.

• Anchoring Force: No less than 1.2 times the specified yield strength of the corresponding rod, ensuring a tight bond between the anchor and the rock mass and effectively resisting various external forces.

• Pullout resistance: Typically ≥ 100 kN, further enhancing the reliability of the anchoring system.

Scope of Application

• Mine tunnel support: Used in coal, metal, and other mining operations to support the roof and side walls of tunnels, effectively preventing rock collapse and ensuring safe working conditions for miners.

• Shaft installation: During the installation of vertical shaft equipment, various equipment and components are secured to ensure shaft structural stability.

• Slope protection: For slopes surrounding mines or rock slopes on the ground, anchoring technology can be used to enhance slope stability and prevent geological disasters such as landslides.

• Other underground projects: Support and reinforce underground projects such as subway tunnels and underground power plants, ensuring safety during construction and subsequent operations.

How to use

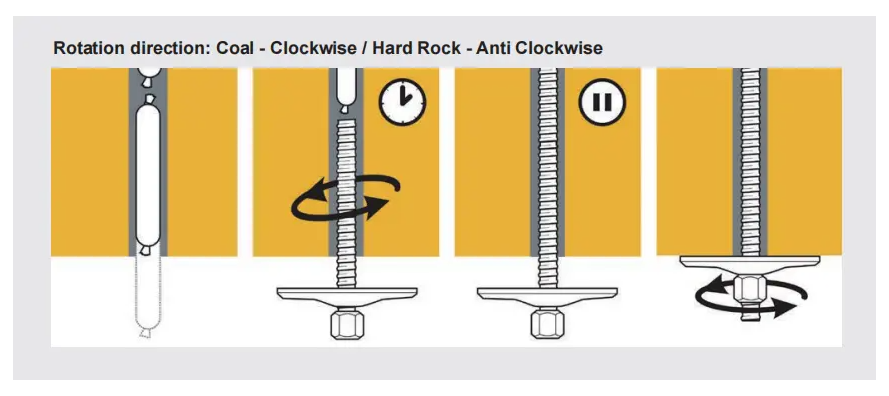

1. Drilling: Use appropriate drilling equipment to drill a hole of the specified diameter and depth into the rock mass according to design requirements.

2. Hole Cleaning: Use high-pressure air or other tools to remove rock dust, debris, and other debris from the borehole to ensure adequate contact between the anchor and the rock mass.

3. Loading the Coils: Slowly place the resin anchor cartridges into the borehole in sequence, taking care not to damage the cartridge packaging.

4. Inserting the Anchor: Quickly insert the anchor into the borehole. Use the anchor stirrer to stir the anchor at the specified speed and time to thoroughly mix the cement and curing agent.

5. Waiting for the Cure: Allow the anchor to cure according to its gel time. Do not disturb the anchor during the curing process.

6. Testing and Acceptance: After curing is complete, test performance indicators such as anchoring strength using methods such as pull-out tests to ensure compliance with design requirements.

Storage and Transportation

• Storage: Store in a dry, ventilated, light- and heat-proof indoor environment. The storage temperature should be below 25°C. The shelf life is generally three months to prevent degradation of the anchor performance.

• Transportation: During transportation, avoid exposure to direct sunlight, rain, and severe impact, and keep packaging intact to ensure product quality is not compromised.

Selecting high-quality mining resin anchoring agents is crucial for ensuring safe and efficient mining operations. Their reliable performance and wide applicability provide solid support for mining and other fields, contributing to the stable development of the industry.