The success of any construction project often starts deep in the ground, with the excavation phase. Picking the right equipment for your specific excavation job is super important. It’s not just about digging holes! It’s about doing the job well, keeping everyone safe, and not spending too much money. This article is your friendly guide to help you understand how to choose the best excavation equipment. We’ll look at different types of excavation and the kinds of machinery that can help you get your construction project off to a great start. If your work involves moving earth, then this guide is for you!

1. What Exactly is Excavation and Why is it So Important for Your Construction Project?

So, what is excavation? Think of it as the process of moving earth, rock, or other materials with tools or machinery. It’s one of the very first steps in most construction project tasks. You might need to excavate to build foundations for buildings, create basements, install pipes for water or sewer systems, or even for landscape projects. The importance of excavation cannot be overstated. If the excavation isn’t done right, it can cause big problems for the whole project later on. A good excavation job makes sure the ground is stable and ready for whatever you’re building.

Proper excavation sets the stage for everything else. Imagine trying to build a strong house on a wobbly base – it wouldn’t work very well! That’s why construction professionals pay close attention to this initial phase. Good excavation helps ensure that structures are safe, secure, and will last a long time. It’s also key for things like road building or creating pathways for utility lines. Without careful excavation work, projects can face delays, increased costs, and even safety hazards. So, starting your excavation project correctly is a big step towards success.

2. Exploring the Terrain: What are the Different Types of Excavation Methods?

Not all excavation is the same! There are different types of excavation methods, and the one you choose depends on the job and the terrain. Let’s look at a few common ones:

- Topsoil Excavation: This is when you remove the top layer of soil, often to get to the harder ground underneath or to save the good soil for landscape work later. It involves removing topsoil and rock fragments.

- Earth Excavation: This involves digging and removing large amounts of soil to create space for things like a basement or a foundation.

- Rock Excavation: If the ground is very hard and full of rock, you’ll need special techniques and stronger excavation equipment to break it up and remove it. Sometimes, this involves drilling and careful blasting.

- Muck Excavation: This is when you have to excavate soil that is very wet and muddy, often called “muck.” It can be tricky because the material is unstable.

- Dredging: This special method of excavation is used underwater. Dredging is the process of removing sediments and other materials from underwater beds, like in rivers or harbors, to make them deeper or to gather materials. A dredge is the machine used for this.

- Cut and Fill Excavation: This is a common technique in road building or leveling land. You “cut” (remove) earth from high areas and “fill” (add) it to low areas to create a level surface. This is a smart way to move materials on-site.

Understanding these different types of excavation helps you plan your excavation project better and choose the right tools. Each excavation method has its own challenges and requires specific approaches for safe and efficient work.

3. Digging Deeper: How Does Soil Type and Site Conditions Impact Your Machinery Choice?

The kind of ground you’re working with, or the soil type, makes a huge difference in what excavation equipment you’ll need. Is the ground soft and sandy? Or is it hard clay or full of rocks? Soft soil might be easy to excavate with lighter machinery, but very loose sand might need special care to stop the sides of your trench from collapsing. Hard clay or rocky terrain will need more powerful machines, perhaps even with special attachments to break through. Knowing your soil conditions is step one.

Beyond the soil type, you also have to think about the site itself.

- Accessibility: Can big machines easily get to the excavation area? Narrow pathways or overhead obstacles can limit your choices.

- Space: Are you working in wide-open spaces or confined spaces like between two buildings? Smaller machinery is often needed for tight spots.

- Environmental Concerns: Are there any rules about noise, dust, or protecting nearby nature? This might affect when and how you can excavate.

- Utilities: Are there any underground pipes or cable lines? You must locate these before you dig deep to avoid dangerous and costly accidents. Always get a permit and check for utilities.

Thinking about these things before starting an excavation project will help you choose the most suitable and efficient excavation tools, ensuring the excavation process goes smoothly.

4. The Workhorses of the Site: What Equipment is Commonly Used for Excavation?

When it comes to excavation, there are some key pieces of equipment that you’ll see on most job sites. These powerful machines are designed for digging and moving earth. Here’s a look at some of the most equipment commonly used:

- Excavators: These are probably what most people picture when they think of excavation. An excavator has a long arm (boom), a stick, and a bucket at the end to scoop up earth. They come in various sizes, from mini-excavators for small jobs or confined spaces to huge ones for large projects that can move massive amounts of material.

- Backhoe Loaders: A backhoe loader (often just called a backhoe) is like a Swiss Army knife for excavation. It has a digging bucket on an arm at the back (the backhoe part) and a large loader bucket at the front for pushing or lifting materials. They are very versatile and often used for smaller excavation job tasks and utility work.

- Bulldozers: These are powerful machines with a big metal blade at the front. They are great for pushing large amounts of soil, sand, or debris, and for grading or leveling land.

- Skid Steer Loaders: A skid steer is a small, agile machine. It can have many different attachments, including buckets for digging, augers for drilling holes, and breakers for concrete. They are great for landscape work and tight spaces.

- Trenchers: As the name suggests, trenchers are specialized machines used for digging trenches, usually for laying pipes or cable. They can dig narrow trenches quickly and neatly.

- Dump Trucks: While not diggers themselves, dump trucks are essential for hauling away the excavated material or bringing in fill material. No excavation project is complete without them!

Choosing the right mix of this excavation equipment depends on the scale of your excavation, the soil type, and the specific tasks you need to accomplish. Each of these types of machinery plays a vital role in the construction industry.

5. Beyond the Big Diggers: Are There Specialized Tools for Unique Excavation Tasks?

While excavators and backhoes do a lot of the heavy lifting in excavation, sometimes a job needs more specialized tools. These tools can help with specific challenges or make certain different types of excavation more efficient. For example, if you’re dealing with very hard rock, the bucket on a standard excavator might not be enough. In such cases, hydraulic hammers or ripper attachments can be fitted to the excavator to break up the rock before it’s removed. This is a common need in many construction and excavation projects.

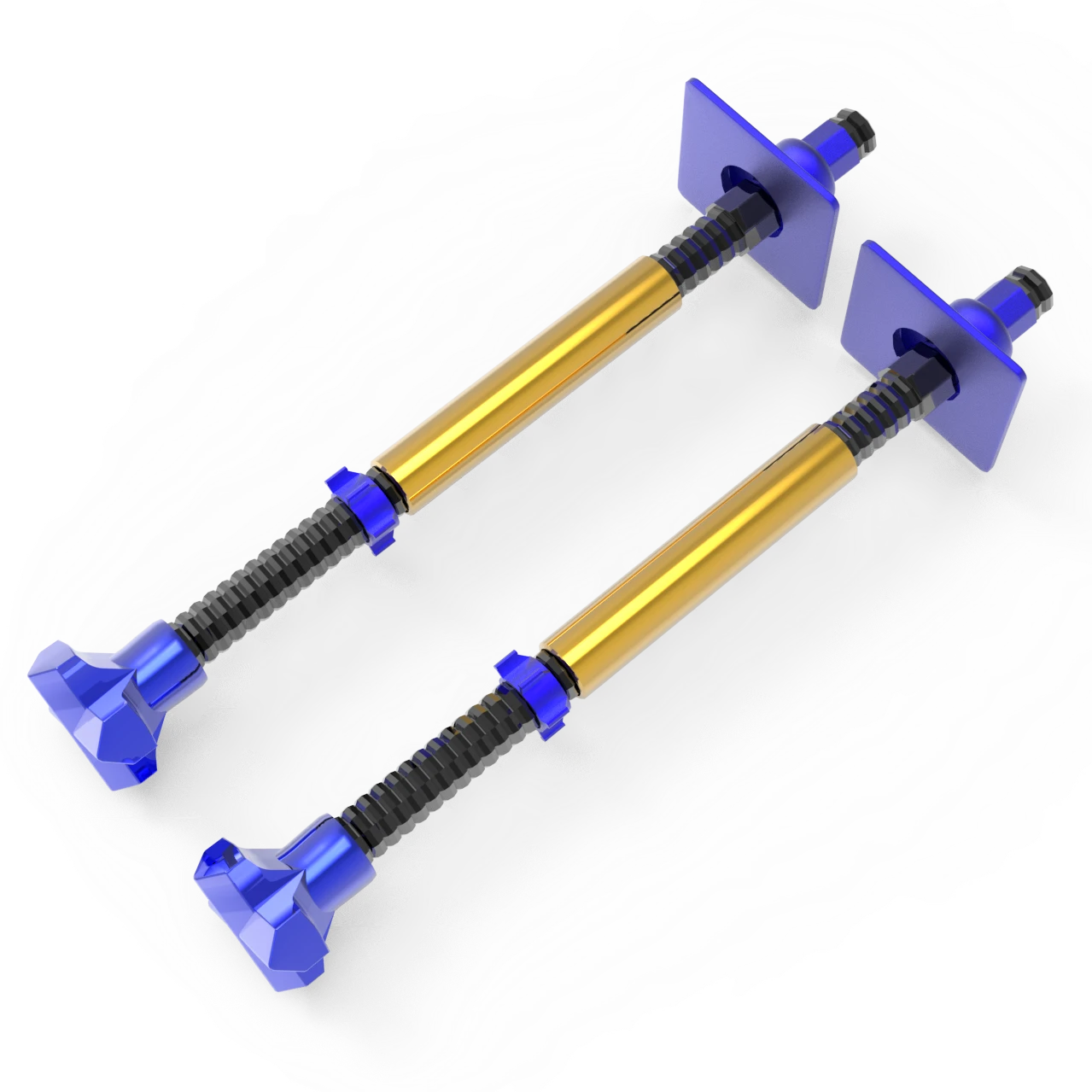

For deep excavation projects, or when working in unstable soil conditions, ensuring the safety and stability of the excavated area is critical. This is where tools and systems for ground support come in. Products like Self-drilling Hollow Anchor systems can be drilled into the surrounding earth to reinforce it and prevent collapses. Similarly, for creating strong anchor points or supporting temporary structures within an excavation, items like Expansion Shell Anchor Bolt products are often used. These specialized tools, while not excavation machinery themselves, are crucial for the safety and success of many excavation tasks, particularly in challenging ground.

These essential tools extend the capability of standard excavation equipment and allow construction professionals to tackle a wider range of excavation challenges effectively. From specialized drill bits for penetrating tough ground to mesh systems for slope stabilization, these additions are vital for a comprehensive approach to excavation.

6. Crucial Foundations: Why are Drainage and Grading Essential in Excavation?

Excavation isn’t just about digging holes; it’s also about managing water and shaping the land. This is where drainage and grading come in, and they are super important aspects of any excavation job. Proper drainage ensures that water doesn’t collect in your excavated area, which could weaken the soil, damage foundations, or make the site unsafe. This might involve creating slopes, digging drainage trenches, or installing pipes to carry water away.

Grading is the process of leveling or sloping the land to meet the engineering specifications of the construction project. Good grading is essential for many reasons:

- It ensures a stable base for foundations.

- It helps with drainage, directing water away from structures.

- It creates the desired shape for roads, building sites, or landscape features.

- It can prevent soil erosion.

Both drainage and grading are closely linked to the excavation process. The way you excavate can affect how water flows and how the land is shaped. Often, the same excavation equipment, like bulldozers and excavators, are used for grading. Ignoring drainage and grading can lead to serious problems down the line, so they must be planned and executed carefully as part of the overall excavation strategy. This ensures the long-term stability and success of the construction project.

7. Safety First: What Protocols Must Be Followed During an Excavation Job?

An excavation job can be dangerous if not managed properly. The ground can be unpredictable, and working with heavy machinery always carries risks. That’s why following strict safety protocols is absolutely essential. Before any digging starts, it’s crucial to identify and mark any underground utility lines – like gas, water, or electrical cable. Hitting one of these can cause serious accidents, service outages, and big fines. Always “Call Before You Dig!” or use a similar service to get a permit and locate utilities.

Here are some key safety protocols for any excavation site:

- Site Inspection: Regularly check the excavation site for any signs of instability, like cracks in the soil.

- Protective Systems: For any trench or excavation deeper than a few feet, you usually need protective systems to prevent cave-ins. This could be shoring (supports for the walls), shielding (like trench boxes), or sloping the sides of the excavation.

- Access and Egress: Provide safe ways for workers to get in and out of the excavation, like ladders or ramps.

- Spoil Piles: Keep excavated soil (spoil piles) and other materials at a safe distance from the edge of the excavation to prevent them from falling in or causing the sides to collapse.

- Operator Training: Ensure that all operators of excavation equipment are properly trained and certified.

- Personal Protective Equipment (PPE): Workers should always wear appropriate PPE, like hard hats, steel-toed boots, and high-visibility vests.

- Awareness: Everyone on-site should be aware of the risks associated with the excavation work.

Safety isn’t just a list of rules; it’s a mindset. Prioritizing safety during excavation protects workers, prevents costly accidents, and keeps the construction project on track.

8. Making the Smart Call: How Do You Select the Most Efficient Excavation Machinery?

Choosing the most efficient excavation machinery means picking tools that get the job done well, on time, and within budget. It’s not always about picking the biggest or most powerful excavator. You need to consider your specific project requirements. Ask yourself: How much material needs to be moved? What is the soil type? How much space do I have? What is my timeline? Answering these questions helps narrow down your choices for the excavation.

Here’s a simple table to help think about it:

| Feature | Small Excavation (e.g., Backyard Landscaping) | Medium Excavation (e.g., House Basement) | Large Excavation (e.g., Commercial Building) |

|---|---|---|---|

| Typical Machine | Mini Excavator, Skid Steer | Backhoe Loader, Medium Excavator | Large Excavator, Bulldozers, Dump Trucks |

| Key Factor | Maneuverability, Precision | Versatility, Moderate Power | Power, Capacity, Speed |

| Soil Concern | Access, minimal disturbance | Stability, Water table | Volume, Rock presence |

For efficient excavation, consider fuel efficiency of the machinery, maintenance needs, and operator skill. Sometimes, renting equipment is more cost-effective than buying, especially for specialized pieces of equipment you don’t use often. Remember, “efficient” also means safe. Don’t cut corners on safety features or operator training to save a little money upfront, as accidents can be far more costly. The goal is to find the right equipment that balances power, precision, cost, and safety for your unique excavation job. This careful selection is a hallmark of well-managed construction and excavation projects.

9. A Word from a Factory Owner: What to Look for When Sourcing Your Tools

As Allen from China, with 7 production lines dedicated to Self-Drilling Anchor Systems and Drilling Tools, I’ve learned a lot about what construction companies and contractors value. While my factory focuses on tools like rock drilling bits, self-drilling anchors, and ground support systems, the principles of sourcing high-quality, reliable products apply broadly, even when you’re considering larger excavation equipment or its critical components.

When you’re looking for suppliers, especially from developing countries, it’s natural to be quality-sensitive while also seeking competitive pricing. This is what many of my customers, like Mark Davis from the USA, look for. Here are a few things I believe are important:

- Quality Inspection: Don’t just take a supplier’s word for it. Ask about their quality control processes. For critical components, like the steel used in anchor bars or the carbide in Rock Drilling Bits, material quality is paramount for durability and safety.

- Certifications: Look for relevant certifications, such as ISO standards. These indicate that a factory adheres to international quality management practices. However, be diligent, as certificate fraud can be an issue. Verify credentials where possible.

- Communication: Clear and efficient communication with supplier sales representatives is vital. Misunderstandings can lead to errors and delays. A responsive supplier who understands your needs is invaluable.

- Logistics and Reliability: Shipment delays can cripple a construction project. Discuss lead times and shipping options upfront. A reliable supplier, like a well-established Self drilling anchor tools factory, will work hard to meet agreed-upon schedules.

- Technical Support: Even if you’re knowledgeable in sales or procurement, having access to good technical support from your supplier can be very helpful, especially when dealing with specialized products like Mine welding wire support mesh for retaining earth in an excavation.

Ultimately, building a good relationship with a trustworthy supplier who provides not just products but also reliable service and support is key. This applies whether you’re buying excavation machinery or the essential tools that support the overall excavation process.

10. The Future of Digging: What Innovations are Shaping Excavation Technology?

The world of excavation and construction machinery is always changing. New technologies are making excavation equipment smarter, safer, and more efficient. One exciting area is automation. We’re starting to see excavators and other machinery that can perform tasks with less direct human control, using GPS and sensors to guide their movements for precise excavation. This can improve accuracy and speed, especially for complex grading or trench excavation jobs.

Telematics is another big trend. This involves collecting data from machines – like how much fuel they’re using, when they need maintenance, or where they are located – and sending it wirelessly to managers. This helps companies use their excavation equipment more effectively and reduce downtime. There’s also a growing focus on sustainability. Manufacturers are developing machinery that uses less fuel and produces fewer emissions, which is better for the environment and can save money on operating costs. Electric and hybrid excavators are becoming more common, especially for work in cities or sensitive areas where noise and pollution are big concerns.

Other innovations include:

- Advanced Attachments: More versatile and intelligent attachments for excavators and other types of machinery that can perform a wider range of tasks.

- Virtual Reality (VR) and Simulation: Used for training operators in a safe environment before they use real excavation equipment on-site.

- Drones: Used for surveying sites, monitoring progress, and even inspecting hard-to-reach areas of an excavation.

These advancements are helping to make the excavation process safer, faster, and more environmentally friendly. As technology continues to evolve, the way we excavate and manage construction projects will keep getting better. For anyone involved in the construction industry, staying aware of these trends is important for remaining competitive and efficient.

Key Takeaways for Your Next Excavation Project:

Choosing the right equipment for your excavation job is a big decision. Here are the most important things to remember:

- Understand Your Project: Know the soil type, site conditions, and the specific goals of your excavation.

- Know Your Equipment: Familiarize yourself with the different types of excavation machinery (like excavators, backhoes, etc.) and their capabilities.

- Safety First, Always: Implement strict safety protocols to protect workers and prevent accidents during excavation. Never skip locating utilities before you dig deep.

- Consider Drainage and Grading: These are vital for the stability and success of your excavation and overall construction project.

- Efficiency is Key: Select machinery that balances power, precision, cost, and safety for your specific excavation needs.

- Specialized Tools Matter: Don’t overlook tools for ground support or specialized tasks that can make your excavation safer and more effective.

- Choose Suppliers Wisely: Look for quality, reliability, good communication, and support when sourcing any equipment commonly used or related tools.

- Stay Updated: Keep an eye on new technologies that can improve your excavation methods and efficiency.

Proper excavation lays the groundwork for a successful construction project. By carefully considering these points, you’ll be well-equipped to tackle your next excavation challenge!

Post time: May-30-2025