We’re going to dive deep into a small but mighty component: the hex shank drill adapter. It might seem simple, but understanding its nuances can save you time, money, and a lot of headaches on the job site. We will explore what it is, why it’s a game-changer for efficiency, how to choose the right one, and what to look for in a quality supplier.

What Exactly is a Hex Shank Drill Bit Adapter and Why Do You Need One?

Let’s start with the basics. In the world of drilling, compatibility is king. You have a powerful drill, and you have a specialized drill bit. But what if they don’t fit together? That’s where an adapter comes in. A hex shank drill bit adapter is a specially designed connector that allows you to use a drill bit with a particular shank type (like a standard round shank) in a drill chuck designed for a different type, specifically a hexagonal or “hex” shank. Think of it as a universal translator for your power tools.

The need for this tool arises from the evolution of drill technology. Modern impact drivers and many high-torque drills have moved towards quick change hex chucks for their superior grip and rapid bit swapping capabilities. However, a vast number of legacy and specialty drill bits, such as masonry bits, auger bits, or even some high-precision bits, still use the traditional smooth, round shank. Instead of buying an entirely new set of expensive hex-shanked bits, a simple bit adapter allows you to leverage your existing inventory, providing incredible flexibility and cost savings.

In my experience working with construction and mining companies, this small piece of metal is a hero in the toolbox. A project manager in Texas once told me, “Allen, your adapters saved my crew half a day. We had the right masonry bits but only impact drivers on-site. Instead of sending someone back to the shop, we just popped on the adapters and kept working.” This is the real-world value of this component: it eliminates downtime and keeps your projects moving forward. It’s not just a piece of metal; it’s an efficiency-driver.

How Does a Hex Shank Differ from a Standard Round Shank?

To truly appreciate the adapter, you must first understand the two primary shank types it connects. The shank is the end of the drill bit that is inserted and held by the chuck of the drill. For a long time, the simple, smooth, cylindrical round shank was the industry standard. It’s still widely used today, especially in traditional drill presses and handheld drills with a three-jaw chuck system.

The hex shank, as the name implies, has a hexagonal cross-section. This design is not arbitrary; it offers a significant mechanical advantage. A drill‘s three-jaw chuck grips a round shank by friction at three points. Under high torque, this can sometimes lead to the bit slipping in the chuck, which can damage both the shank and the chuck, and more importantly, result in a loss of drilling power. The hexagonal shape of a hex shank, however, fits securely into a corresponding hex chuck, creating multiple flat contact surfaces that prevent rotation and slippage. This ensures that 100% of the drill’s torque is transferred directly to the bit.

Here’s a simple breakdown to visualize the difference:

| Feature | Standard Round Shank | Hex Shank |

|---|---|---|

| Shape | Cylindrical/Smooth | Six-sided/Hexagonal |

| Grip Mechanism | Friction-based (3-jaw chuck) | Interlocking flat surfaces |

| Torque Transfer | Good, but prone to slippage under high load | Excellent, virtually no slippage |

| Bit Changes | Requires manual tightening/loosening of the chuck | Often used in quick-release/quick change systems |

| Best For | General purpose drilling, drill presses | High-torque applications, impact drivers, speed |

As you can see, the move towards the hex shank is a move towards efficiency and power. This is particularly critical in geotechnical and mining applications where you’re drilling into tough materials like rock and concrete. The unyielding grip ensures maximum impact and rotational force, which is essential for our specialized rock drilling bits.

Are All Hex Drill Adapters the Same? Exploring the Variations.

A common question I get from procurement officers is, “An adapter is an adapter, right? Just send me the cheapest one.” This is a dangerous oversimplification. While they may look similar, not all hex shank drill adapter units are created equal. The variations in design, material, and manufacturing precision can have a huge impact on performance and safety. As a factory owner, I see these differences firsthand on the production floor.

The most common variation is size. The hex portion of the shank is typically a standard 1/4-inch diameter, which is the most widely used size for impact drivers and bit holders. However, the other end of the adapter—the chuck that holds the actual drill bit—can come in various sizes to accommodate different bit shank diameters. You can find them with small chucks for tiny pilot bits all the way up to larger ones for heavy-duty auger bits. It’s crucial to match the adapter’s chuck capacity to the bits you intend to use.

Furthermore, there are differences in the locking mechanism. Some adapters have a simple three-jaw chuck that you tighten with a key, just like a standard drill. Others feature keyless chucks for faster manual tightening. The most advanced versions are part of a quick change system, often with a ball detent or magnetic lock that provides a secure, snap-in fit. The choice depends on your application’s demand for speed versus holding power. For a heavy duty job, a keyed chuck might offer a more secure grip, while for rapid assembly work, a keyless or magnetic adapter is far more efficient.

What is the Advantage of a Quick Change Hex Shank System?

Efficiency is the currency of the modern construction and mining site. Every minute saved is money earned. This is where the quick change system, built around the hex shank, truly shines. Imagine a worker on a scaffold, needing to switch from drilling a pilot hole to driving a screw. With a traditional keyed chuck, this process is cumbersome and slow. It involves finding the chuck key, loosening the chuck, swapping the bit, re-tightening it, and then putting the key away. This can take up to a minute or more.

A quick change system reduces this process to seconds. The chuck on the drill has a sliding collar. To insert a bit or an adapter, you simply push it in until it clicks into place. To release it, you pull the collar back, and the bit pops out. It’s a one-handed operation that can be done in under five seconds, even with gloves on. When you multiply this time saving across a whole crew and an entire project, the gains in productivity are massive.

“The switch to quick-change systems on our sites cut down our assembly and installation times by nearly 15%. It seems small, but over a year, that’s a huge operational win for us.” – A quote I remember from a long-term partner in Australia.

This system’s reliability hinges on the precise manufacturing of the hex shank drill bits and adapters. The hexagonal shape and the locking groove must be machined to exact tolerances to ensure a secure fit without any “wobble.” Any imperfection can lead to poor performance and premature wear. This is why, at our facility, we use CNC (Computer Numerical Control) machining to guarantee that every hex shank drill adapter we produce meets these exacting standards.

Can You Use a Standard Drill Bit in a Hex Drill? The Role of the Adapter.

This is perhaps the most practical question a professional will ask. You have a new, powerful impact driver with a 1/4-inch hex chuck, but your trusted set of high-quality, job-specific drill bits are all round shank. The answer is yes, you absolutely can, and the hex shank drill adapter is the key. You cannot directly insert a round shank bit into a hex chuck; it won’t hold securely and will either spin uselessly or fall out.

The adapter acts as the crucial intermediary. You first secure the round shank bit into the chuck end of the adapter, tightening it down just as you would with a standard drill. Then, you take the entire assembly—the adapter with the bit now firmly in its grip—and insert the adapter’s hex shank end into your impact driver’s quick change chuck. In an instant, you’ve converted your standard bit into a hex-compatible tool.

This capability is invaluable. It means you don’t have to abandon your investment in high-quality, specialized bits like those used for masonry, metalwork, or glass. It gives you the best of both worlds: the torque and speed of your modern drill and the precision and versatility of your existing drill bit collection. For procurement managers like Mark, this means you can upgrade your company’s power tools without the massive secondary expense of replacing every single bit in your inventory. It’s a smart, cost-effective strategy.

Choosing the Right Material: Why Steel Quality Matters for Durability.

An adapter is subjected to immense force. All the torque and impact energy from the drill is channeled through this small component. If it’s made from inferior materials, it will fail—period. This is a topic I am very passionate about because safety and reliability are paramount. The best adapters are made from high-grade, hardened steel.

When you’re evaluating a supplier, ask them about the specific type of steel they use. Common choices include Chrome-Vanadium (Cr-V) steel, known for its strength and toughness, and S2 tool steel, which is even harder and more resistant to shock, making it ideal for impact-rated adapters. The manufacturing process is just as important as the raw material. Look for adapters that have been properly heat-treated. This process alters the steel’s microstructure, significantly increasing its hardness and durability without making it brittle.

At our factory, we have a multi-stage quality control process.

- Material Inspection: We test the raw steel to ensure it meets our specifications for hardness and composition.

- Precision Machining: CNC machines cut the adapter to precise dimensions.

- Heat Treatment: The components are heat-treated in a controlled environment to achieve the optimal balance of strength and flexibility.

- Batch Testing: We randomly select adapters from every production run and subject them to extreme torque and stress tests to ensure they exceed performance standards.

A poorly made adapter won’t just break; it can shatter, sending metal fragments flying. It can also damage the drill’s chuck or the drill bit itself. Investing in a quality-made steel adapter from a reputable source isn’t just about performance; it’s about job site safety and protecting your investment in other tools.

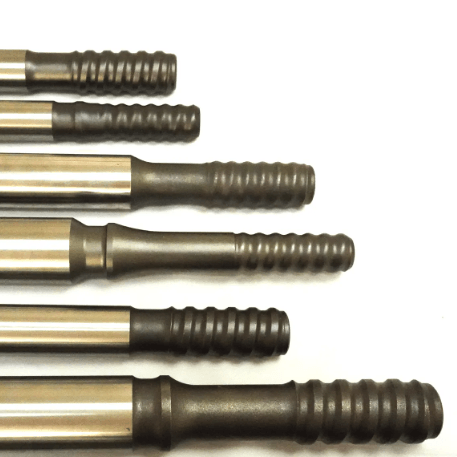

What are Threaded Hex Adapters and Their Specific Applications?

While most of our discussion has focused on adapters that have a chuck on one end, there is another important variation: the threaded hex adapter. Instead of a chuck to hold a bit, this type of adapter has a male thread on one end and a hex shank on the other. This design serves a very different but equally critical purpose, particularly in anchoring and installation work.

Their primary function is to connect a power drill to a threaded component, such as a threaded rod, an anchor bolt, or a wire brush with a threaded arbour. For example, in our field of self-drilling anchor systems, you might need to drive a threaded rod into a pre-drilled hole filled with resin. A threaded hex adapter allows you to use a powerful, high-torque impact driver to do this quickly and efficiently, ensuring the rod is seated perfectly. This is far faster and provides more consistent torque than turning it by hand with a wrench.

These adapters are essential for installing a wide range of hardware, from setting concrete anchors to assembling steel frames. They also come in various thread sizes (both metric and imperial) to match the bolts or rods being used. When sourcing these, it is vital to ensure the threads are clean and precisely cut to prevent cross-threading, and that the body is made from the same high-strength, impact-rated steel as a chuck adapter. The forces involved in driving large threaded components are immense, and failure is not an option. This is why we manufacture a range of specialized threaded drill bits and adapters to meet these demanding applications.

Common Mistakes to Avoid When Using a Hex Shank Drill Adapter.

Even the best tool can underperform or become a hazard if used incorrectly. Over the years, I’ve heard feedback from the field and identified a few common, preventable mistakes people make when using a hex shank drill adapter. Sharing this knowledge can help your teams work more safely and effectively.

- Not Fully Seating the Shank: The most common error is not pushing the hex shank all the way into the drill’s chuck until it “clicks.” If it’s not fully seated, the locking mechanism won’t engage properly. The adapter will have excessive wobble, leading to inaccurate drilling, and it could even fly out of the drill under load. Always give it a gentle tug to confirm it’s locked in place.

- Using a Non-Impact-Rated Adapter in an Impact Driver: There is a significant difference between a standard drill and an impact driver. An impact driver delivers rotational force in short, powerful bursts. An adapter not specifically rated for impact use will quickly fail under this stress. Always check that the adapter is marked as “impact-rated” if you plan to use it with an impact tool.

- Over-tightening the Chuck (Manual Chucks): For adapters with a manual chuck, there’s a temptation to apply excessive force when tightening the bit. This can damage the internal gears of the chuck and make it difficult to release the bit later. Tighten it firmly, but don’t use a cheater bar or wrench to get extra leverage.

- Ignoring Wear and Tear: Like any tool, adapters wear out. Inspect them regularly for signs of wear, such as rounded hex corners, cracks in the body, or a chuck that no longer grips tightly. Using a worn-out adapter is a risk. It’s much cheaper to replace a single adapter than to deal with a failed project or a damaged power tool.

How Do We Ensure Quality and Compliance in Our Drill Adapters?

This is the question that truly separates a reliable partner from a simple supplier. For a procurement officer like Mark, who has faced issues with quality and fraudulent certificates, this is the most important question of all. At my company, our reputation is built on trust, and that trust is earned through a transparent and rigorous quality assurance process.

First, Certification. We proudly maintain our ISO 9001 certification, which governs our quality management systems. This isn’t just a piece of paper for us; it’s the framework for our entire operation, from sourcing raw materials to final inspection. When a client requests our certificates, we provide them directly and are happy to have them verified. We understand the damage that certificate fraud causes in our industry and stand for complete transparency.

Second, Traceability. Every batch of products we create, from high-quality shank adapters to complex anchor bolts, is assigned a unique batch number. This number follows the products through every stage of production. If a problem is ever detected, we can trace it back to the specific batch of raw material and the exact date it was produced. This allows us to contain any issues and ensures accountability.

Finally, Communication. We know that communication breakdowns are a major pain point. Our sales and technical teams are trained to provide clear, prompt, and honest information. If there’s a potential delay in a shipment, you will know about it as soon as we do, along with a clear plan to mitigate it. We see our clients as partners, and a strong partnership is built on open communication. We understand that a delayed shipment for you means a delayed project, and we do everything in our power to honour our commitments.

What Does the Future Hold for Drill and Adapter Technology?

The world of tools is always evolving, and it’s exciting to be a part of it. Looking ahead, I see a few key trends shaping the future of drilling and adapter technology. Materials science will continue to play a huge role. We are constantly researching new steel alloys and composite materials that could offer even greater strength-to-weight ratios, leading to lighter yet more durable tools.

Smart technology is also on the horizon. Imagine a drill and adapter system that can sense the torque being applied and the material being drilled, automatically adjusting the speed and impact force for optimal performance. This could prevent bit breakage, extend tool life, and ensure perfect installations every time. While this is still in the advanced stages of development, the integration of sensors and microprocessors into power tools is an undeniable trend.

Finally, the push for system-wide compatibility will continue. As manufacturers, we have a responsibility to make our tools work together seamlessly. This means adhering to international standards for things like shank size and thread patterns. The goal is a future where a professional can confidently pick up any drill and any bit or adapter, knowing they will work together flawlessly. It’s a future of increased efficiency, safety, and productivity that we are dedicated to helping build, one high-quality component at a time.

Key Takeaways to Remember

- A hex shank drill adapter is a vital tool that allows you to use standard round-shank bits in modern hex-chuck drills, saving money and increasing versatility.

- The hexagonal shank provides a superior, non-slip grip compared to a round shank, ensuring maximum torque transfer from the drill to the bit.

- Not all adapters are the same. Look for high-quality, impact-rated steel (like Cr-V or S2) and precision manufacturing to ensure durability and safety.

- Quick change systems dramatically improve on-site efficiency by reducing the time it takes to swap bits to mere seconds.

- Always use the right adapter for the job, paying attention to impact ratings and avoiding common mistakes like not seating the shank fully.

- Choose a supplier who values quality and transparency, with verifiable certifications (like ISO 9001), a robust quality control process, and clear communication. Your peace of mind is worth it.

Post time: Jun-09-2025