Introduction

In mineral development, roadway support is a critical aspect of ensuring underground safety. Mining support trays, as key components of support systems, are widely used in coal mines, metal mines, and tunneling projects to distribute pressure, secure anchor rods, and reinforce roof structures. This article explores the types, functions, selection criteria, and applications of mining support trays, helping industry professionals optimize support solutions for enhanced safety and productivity.

1. Types of Mining Support Trays

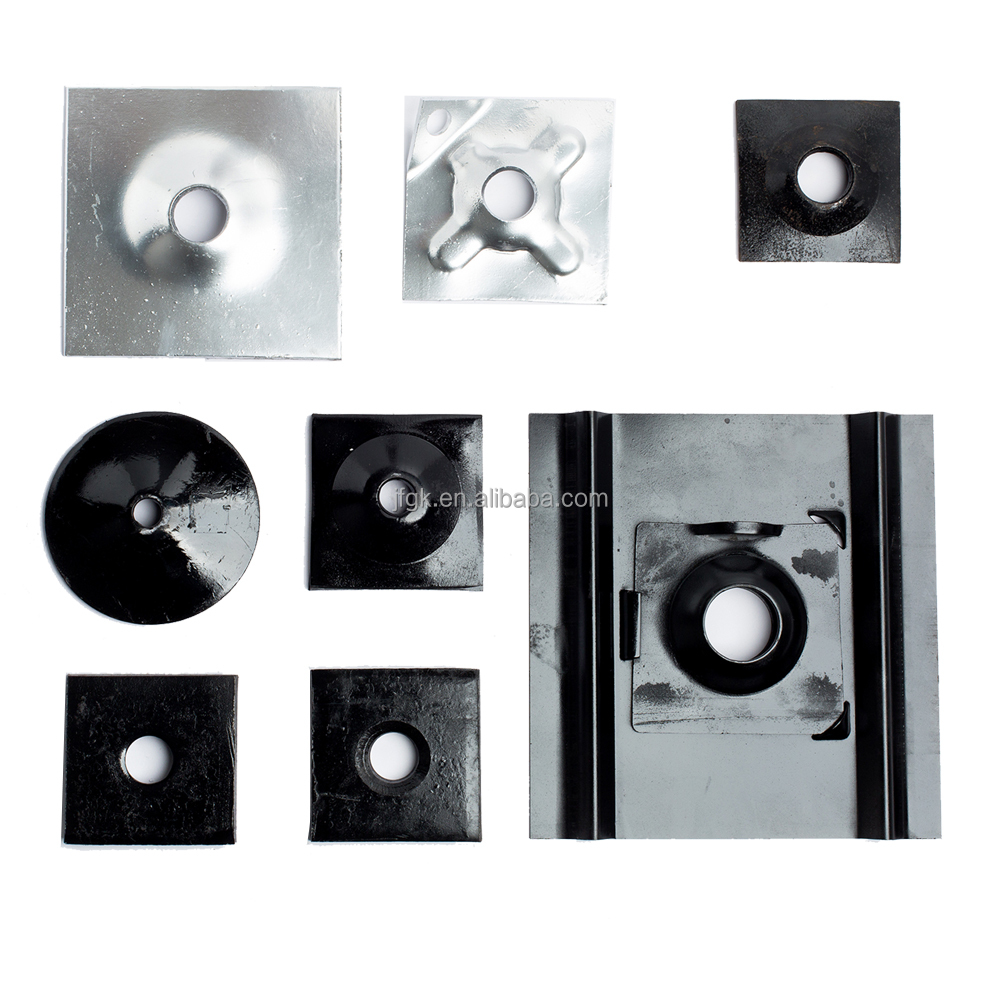

Mining support trays can be categorized based on material, structure, and purpose:

1.1 By Material

Metal Trays

Steel Trays (e.g., Q235 steel): High strength and toughness, ideal for dynamic loads (e.g., conveyor bases).

Cast Iron Trays: Excellent compressive strength but brittle, suitable for static support.

Composite Trays (e.g., nylon, UHMWPE)

Lightweight, corrosion-resistant, ideal for humid or acidic environments.

Concrete Trays

Cost-effective but heavy, mainly used for permanent support structures.

1.2 By Structure

Flat Trays: Used in bolt support systems to distribute roof pressure.

Grooved Trays: Secure rails or pipelines to prevent displacement.

Self-Aligning Trays: Paired with spherical washers to balance bolt tension.

Articulated Trays: Adjustable for irregular roof support.

1.3 By Function

Bolt Trays: Work with anchor rods and cables to enhance roof stability.

Rail Trays: Fix mine cart tracks in place.

Conveyor Trays: Serve as foundational supports for belt conveyors.

2. Key Applications of Mining Support Trays

2.1 Roof Support

In coal and metal mining, roof collapse is a major hazard. Bolt support systems (including trays, rods, and nuts) reinforce rock layers to prevent cave-ins. Trays play a crucial role by:

Distributing bolt tension for stronger support.

Preventing bolt loosening over time.

Recommended Trays:

Soft or fractured rock → Self-aligning or articulated trays.

High-pressure environments → High-strength steel or cast iron trays.

2.2 Rail Fixation

Underground transport systems rely on stable rail tracks. Rail trays:

Secure sleepers to prevent track movement.

Reduce wear and extend rail lifespan.

Recommended Trays: Grooved steel trays or adjustable rail trays.

2.3 Equipment Base Support

Heavy machinery like conveyors and hydraulic supports require stable foundations. Trays help by:

Distributing equipment load to prevent subsidence.

Minimizing vibration impact.

Recommended Trays: Reinforced steel trays or adjustable support trays.

2.4 Temporary Support

For rapid tunneling or temporary roadway support, lightweight trays (e.g., nylon) improve installation speed and reduce costs.

3. How to Choose the Right Mining Support Tray?

3.1 Load Requirements

Static high pressure (e.g., permanent support) → Cast iron or concrete trays.

Dynamic vibration (e.g., conveyor bases) → Steel trays.

3.2 Environmental Factors

Humid/corrosive conditions → Stainless steel or composite trays.

High-temperature zones → Heat-resistant steel trays.

3.3 Installation Efficiency

Quick assembly needed → Pre-drilled or lightweight nylon trays.

Adjustability required → Articulated or self-aligning trays.

3.4 Cost Considerations

Short-term projects → Economical concrete or composite trays.

Long-term use → Durable steel trays.

4. Maintenance and Safety Tips

Regular inspections: Check for deformation or cracks, especially on bolt trays.

Rust prevention: Apply anti-corrosion coatings or use galvanized metal trays in wet environments.

Bolt tightening: Periodically secure rail tray fasteners to prevent loosening.

5. Conclusion

Mining support trays are vital for safe and efficient underground operations. Selecting the right material and design based on geological conditions, load demands, and environmental factors can significantly improve support performance while reducing maintenance costs.

For technical specifications or custom solutions, contact our expert team today!

Post time: Jul-15-2025