Introduction: The Anchoring Dilemma

In ground support and structural reinforcement, choosing between resin anchoring agents (polyester-based) and epoxy anchoring agents is more than a cost decision—it’s a safety imperative. Misalignment with project conditions can lead to catastrophic failures. Let’s dissect their science and applications.

1. Chemical Core: Fast vs Strong

Property Resin Anchors Epoxy Anchors

Base Chemistry Unsaturated polyester + styrene Epoxy resin + amine hardener

Reaction Type Radical polymerization (exothermic) Polyaddition (low exotherm)

Curing Speed 30 sec – 3 min (rapid support) 5 min – 2 hr (precision cure)

Peak Temperature 80-120°C (rock damage risk) 40-60°C (thermal-stable)

2. Performance Showdown: When Each Wins

✅ Resin Anchors Excel In:

Dry, Short-Term Projects: Coal mine roadway support requiring instant load-bearing.

Budget Constraints: Costing 60-80% less than epoxy (e.g., $1.5/kg vs $8/kg).

✅ Epoxy Anchors Dominate In:

Critical Infrastructure: Bridges, nuclear plants (e.g., Hong Kong-Zhuhai-Macao Bridge used SIKA epoxy).

Harsh Environments:

▶ Wet tunnels (>8% moisture)

▶ Coastal salt spray zones

▶ Dynamic load areas (mine hoist foundations)

3. The Durability Gap: 10X Lifespan Difference

Resin: Loses 30% strength in 1 year due to hydrolysis; fails in pH<5 or pH>9 environments.

Epoxy: Maintains >90% strength after 10 years (per ISO 2812 corrosion tests).

Case Study: MINOVA AXCEL™ epoxy anchors in South African gold mines (3km depth) withstood 30kJ rockburst impacts.

4. Cost Analysis: Beyond Unit Price

Cost Factor Resin Anchor Epoxy Anchor

Material Cost $1.5 – $3/kg $8 – $20/kg

Installation Requires dry surfaces + mixer Hand-mix in damp conditions

Failure Repair High (30% rework in wet mines) Near zero

Total Ownership $15/m² over 5 years $9/m² over 20 years

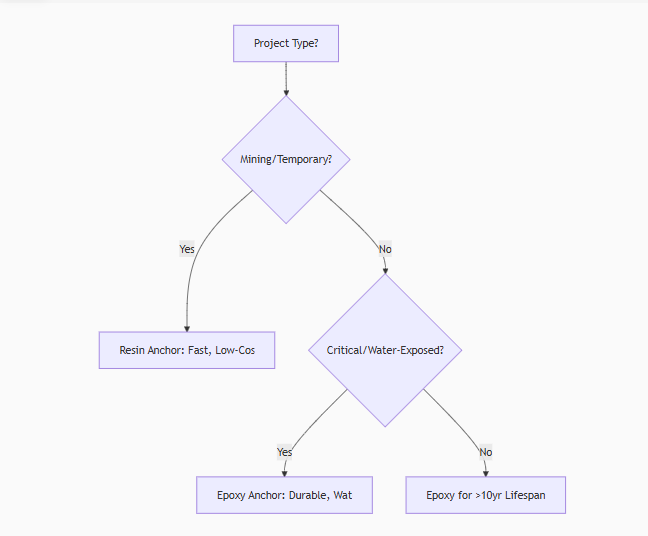

5. How to Choose: Decision Flowchart

6. Industry-Leading Solutions

Resin Anchors: MINOVA CARBOGRID™ for rapid coal mine bolting (45-sec cure).

Epoxy Anchors: BASF MasterInject® 1300 for seismic zone foundations.

Conclusion: Match Chemistry to Challenge

Resin anchors deliver speed and economy in dry, shallow projects. But when facing water, corrosion, or long-term loads, epoxy’s molecular resilience becomes non-negotiable.

Post time: Jul-22-2025