High-Strength Twisted Anchor Rod – Global Geological Support for Tunnels & Mines | Jiufu

High-Strength Twisted Anchor Rod - Global Geological Support Solution for Tunnels & Mines

| Key Parameters | Standard Specifications | Customization Range | Global Compatibility Standards | Performance Indicators |

| Anchor bolt diameter | 18mm/20mm | 16-25mm | Complies with ISO 898-1 and ASTM A325 standards | Tensile strength: ≥500 Mpa |

| Length | 1-3m | 1-5m | Compatible with Vietnamese TCVN and Australian AS standards | Yield strength: ≥350 Mpa |

| Surface treatment | Hot-dip galvanized (430g/㎡) | Hot-dip galvanizing (430-600g/㎡), epoxy coating | Corrosion resistance level up to C5-M (ISO 12944) | Initial anchoring force: 8-12 Tons |

| Twist pitch | 20mm | 15-30mm | Meets EU CE certification requirements | Service life: ≥10 years |

| Supporting components | Washers, nuts, shear pins | Customized anchor heads, resin capsule adapters | - | Installation efficiency: ≤10 minutes/piece |

For Southeast Asian tunnel projects, we offer 18mm diameter twisted anchor rods with 20mm pitch to fit narrow drill holes; for African mines, 20mm diameter with enhanced tensile strength (≥550 Mpa) to withstand hard rock conditions—tailored to local geological needs.

Core Product Characteristics

1. Superior Material & Structural Design

2. Multi-Scenario Adaptability

3. Customizable Surface Treatments

Key Advantages

1. Enhanced Anchoring Performance

2. Efficient Installation & Cost Savings

3. Global Quality & Compliance

4. Tailored Solutions & Global Support

Installation Guidelines

Why Choose Jiufu’s Twisted Anchor Rod?

(2) For permafrost regions (such as Siberia), low-temperature resin capsules should be used, and the bolts should be installed within 5 minutes to prevent the resin from freezing.

Customization Service

Customization Options:Diameter (16-25mm), length (1-5m), surface treatment (hot-dip galvanizing thickness, epoxy coating), pitch (15-30mm), matching components (custom anchor heads, resin capsules).

Customization Process:Send requirements (drawings/samples) → Get quote within 24h → Confirm sample (free for orders over 1000pcs) → Mass production (ISO9001 certified) → Direct shipping to your project site.

Global Shipping & After-Sales

Shipping Terms:Support FOB (Tianjin Port), CIF (Ho Chi Minh Port), DDP (Johannesburg Port) — 7-20 days delivery to major project regions (e.g., Southeast Asia 7-10 days, Africa 12-15 days).

After-Sales Service:24/7 technical support via WhatsApp/email; free replacement for defective products within 1 year; on-site installation guidance for orders over 5000pcs.

1. How to start an OEM order?

Send drawings or sample-Getting price-Payment-Make mold-Confirm sample-Mass production-Payment-Delivery.

2. What is your terms of payment?

We accept TT, L/C, Trade Assurance, Credit card, Western Union etc.

3. Could you customize the packing?

The logo, carton ans pallet can be customized.

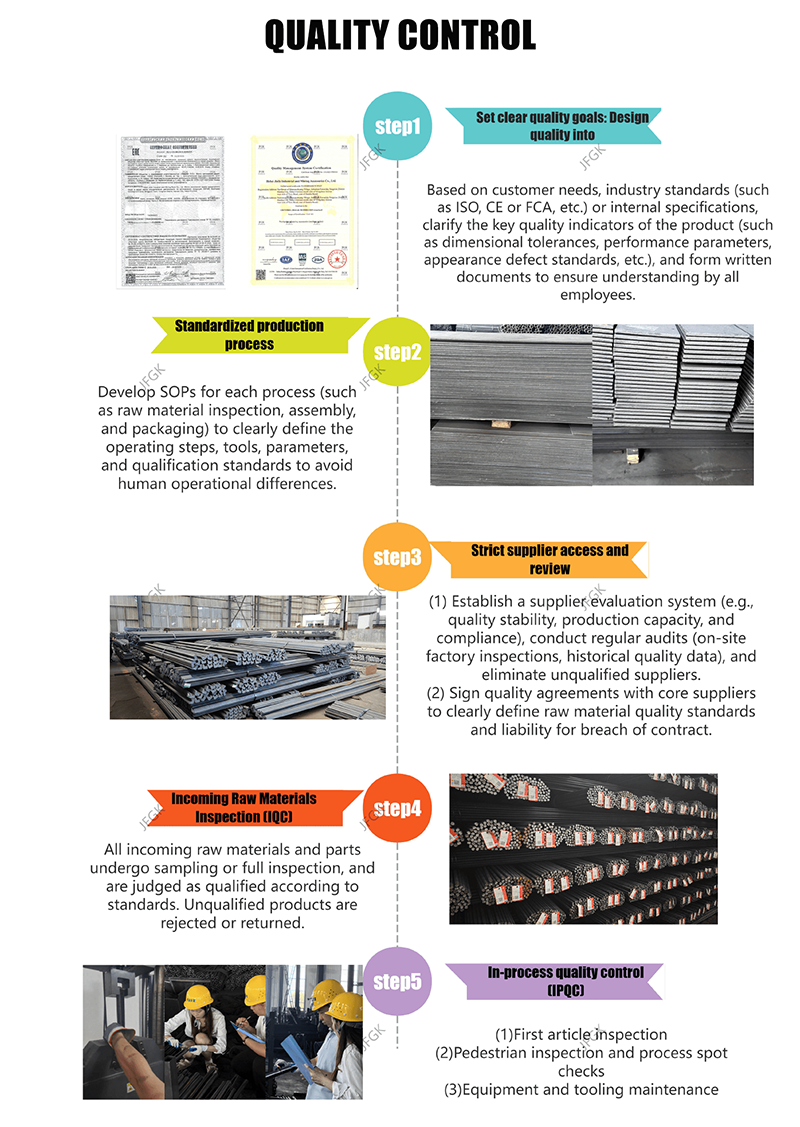

4. How do you ensure product quality?

Better control from raw material, production, processing packing, storage until to shipment.And we passed the IS09001 quality management system certification.

5.What kind of payment term you use to ship the goods?

We support FOB, CIF, CFR, DDU, DDP etc, we got very rich experience shipping goods directly to customers plant.

6.After-sales.

Quick response day and night.