47mm Split Set Stabilisers – Global Mining Support Solution for 150+ Countries | Jiufu

Product Description

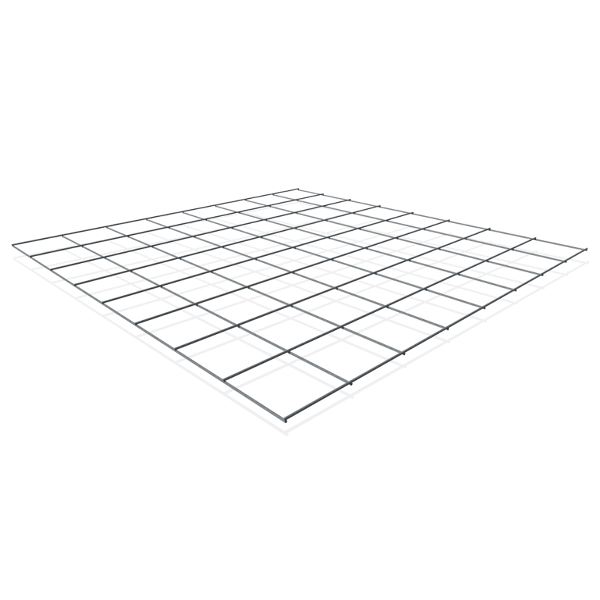

Underground mining, tunnel construction, and infrastructure projects demand reliable ground support that’s easy to install and durable. Jiufu’s 47mm Split Set Stabilisers are engineered to solve these challenges—delivering strong friction anchoring, no need for anchoring agents, and adaptability to harsh environments from Siberian permafrost to South African deep mines.

Application Scenarios

47mm Split Set Stabilisers – Global Mining Support Solution Suitable for scenarios where there are comprehensive requirements regarding support strength, construction efficiency, and cost control.

Application Area 1: Underground metal/non-metal mines

Roadway Support: Used for supporting the roof and sides of development roadways, transportation roadways, and ventilation roadways.

Stope Support: Used in stopes of mining methods such as room-and-pillar mining and shrinkage stoping to support the roof and rock pillars.

Key Advantages: Quick installation (no resin or cement anchoring required), provides immediate frictional support, and is ideal for the rapid excavation needs of mines.

Application Area 2: Tunnels and Underground Chambers

Soft to medium-hard rock tunnels: Used in the initial support of railway, highway, and hydraulic tunnels, forming a combined support system with shotcrete and steel mesh.

Chamber reinforcement: Used for local reinforcement of large-span spaces such as substations, water reservoirs, and underground power plants.

Key advantages: Has a certain adaptability to surrounding rock deformation and can continuously provide support resistance as the surrounding rock deforms.

Application Area 3 - Temporary Support for Slopes and Excavations

Rock slope engineering: Used for shallow reinforcement and surface protection of unstable slopes.

Excavation engineering: Used as temporary support for excavation slopes or as a component of composite soil nail walls.

Key advantages: Fast construction speed and flexible integration with other support methods.

Application Area 4: Emergency Reinforcement and Repair Engineering

Reinforcement of supported areas: Rapid reinforcement and strengthening of areas where existing support has failed or is insufficient.

Emergency rescue engineering: Can be quickly installed in emergency situations such as roof falls and side collapses to control the situation.

Key advantage: Its immediate load-bearing characteristics make it indispensable in rescue operations and rapid repairs.

Model selection and customization

| Key Specifications | Customization Range | Performance Benchmark |

| Bolt Diameter | 47mm (fixed) | Yield Strength: Min. 345 Mpa |

| Length | 1-3m (customizable up to 5m) | Ultimate Tensile Strength: Min. 470 Mpa |

| Wall Thickness | 1-4mm (2.5/3/3.2mm standard) | Initial Anchorage: 6-10 Tons |

| Surface Finish | HDG (430-600g/㎡), Electro-galvanized, Epoxy Coating | Breaking Capacity: Min. 133KN |

Core Advantages

47mm Split Set Stabilisers - Global Mining Support Solution are manufactured from high-strength steel strip, providing superior rock support performance and facilitating a high-quality galvanizing process. Hot-dip galvanizing (430-600 g/m²) provides excellent corrosion resistance in damp or highly corrosive mine environments, exceeding industry standards and ensuring long-term use.

Customization Service

1.Customization options:Size (length/wall thickness), surface finish (HDG thickness 430-600g/㎡ customizable), packing (custom logo, carton, pallet), material composition (adapt to national standards of different countries).

2.Customization Process:Send your requirements (drawings/samples) → Get a customized quote within 24 hours → Confirm sample → Mass production (ISO9001 certified) → Direct shipping to your plant.

3.Adaptation standards:Compliant with international standards (ISO) and local regulations of 150+ countries (e.g., Russia, Australia, USA, South Africa) — no need to modify for regional use.

1. How to start an OEM order?

Send drawings or sample-Getting price-Payment-Make mold-Confirm sample-Mass production-Payment-Delivery.

2. What is your terms of payment?

We accept TT, L/C, Trade Assurance, Credit card, Western Union etc.

3. Could you customize the packing?

The logo, carton ans pallet can be customized.

4. How do you ensure product quality?

Better control from raw material, production, processing packing, storage until to shipment.And we passed the IS09001 quality management system certification.

5.What kind of payment term you use to ship the goods?

We support FOB, CIF, CFR, DDU, DDP etc, we got very rich experience shipping goods directly to customers plant.

6.After-sales.

Quick response day and night.