39mm Split Set Stabilisers – Global Mining Support Solution for 150+ Countries | Jiufu

Product Description

The 39mm Split Set Stabilizers are a "heavy-duty weapon" in the field of geotechnical support, designed specifically to tackle difficult and critical support challenges.

Underground mining, tunnel construction, and infrastructure projects demand reliable ground support that’s easy to install and durable. Jiufu’s 47mm Split Set Stabilisers are engineered to solve these challenges—delivering strong friction anchoring, no need for anchoring agents, and adaptability to harsh environments from Siberian permafrost to South African deep mines.

The main features of the 39mm specification are higher rigidity and greater radial expansion force. This brings the following advantages:

1.Higher load-bearing capacity: It can withstand greater rock mass loads and deformation pressures.

2.Better shear resistance: The thicker pipe wall makes it less likely to be sheared off when the rock mass shifts.

3.Greater anchoring force: It has a larger contact area and friction with the borehole wall.

Main Application Scenarios

1. Soft Rock, Fractured Rock Strata, and High-Stress Roadways

Scenario Description: This applies to mining and preparation roadways in coal and metal mines, as well as tunnels encountering fault zones, fractured zones, and areas of intensely weathered soft rock (such as mudstone, shale, and fractured sandstone).

Why it's suitable: In these rock formations, the rock mass has poor self-stability and is prone to roof falls and sidewall collapses. 39mm large-diameter anchor bolts provide stronger initial support and radial restraint, effectively controlling early loosening and deformation of the surrounding rock and preventing fractured rock fragments from falling.

2. Roadways affected by intense mining activity or dynamic pressure

Scenario description: When the working face is being mined, the adjacent roadway in front of it will be severely affected by the advanced support pressure; or the roadway is located near other active mining areas and is subjected to repeated disturbances.

Why it is applicable: The higher stiffness and strength of 39mm anchor bolts can better resist periodic and impact-induced mining pressure manifestations, maintaining the stability of the support system and preventing anchor bolt failure due to repeated loading.

3. Large-section chambers or critical engineering locations

Scenario description: Large-section, complex-shaped chambers in coal mines, such as shaft entrances, intersections, pump rooms, substations, or the intersection of the main tunnel and cross passages in tunnels.

Why it is applicable: These areas experience stress concentration and extensive surrounding rock damage, requiring a support system that provides extremely high reliability and safety reserves. 39mm rock bolts, used as the main or reinforcing support units, can significantly enhance the strength of the overall support structure.

4. Situations requiring rapid installation and immediate prestressing

Scenario description: Emergency repair projects, rapid tunneling work faces, and situations requiring support immediately following the excavation face.

Why it's suitable: One of the biggest advantages of split-set rock bolts is their "install and use immediately" feature. They provide an initial anchoring force of approximately 30-50 kN instantly after installation. The 39mm specification provides a greater initial force while ensuring rapid installation, allowing for faster control of surrounding rock deformation.

5. As permanent support or long-term support for mine roadways

Scenario description: Long-service life transportation main roadways, ventilation roadways, permanent tunnels, etc.

Why it is suitable: Although slotted pipes may not be suitable for ultra-long-term support in some environments due to corrosion issues, in dry or non-corrosive environments, the 39mm specification is often chosen as part of a permanent support system due to its higher durability and deformation resistance.

Model selection and customization

| Key Specifications | Customization Range | Performance Benchmark |

| Bolt Diameter | 39mm (fixed) | Yield Strength: Min. 345 Mpa |

| Length | 1-3m (customizable up to 5m) | Ultimate Tensile Strength: Min. 470 Mpa |

| Wall Thickness | 1-4mm (2.5/3/3.2mm standard) | Initial Anchorage: 6-10 Tons |

| Surface Finish | HDG (430-600g/㎡), Electro-galvanized, Epoxy Coating | Breaking Capacity: Min. 133KN |

Core Advantages

39mm Split Set Stabilisers - Global Mining Support Solution are manufactured from high-strength steel strip, providing superior rock support performance and facilitating a high-quality galvanizing process. Hot-dip galvanizing (430-600 g/m²) provides excellent corrosion resistance in damp or highly corrosive mine environments, exceeding industry standards and ensuring long-term use.

Customization Service

1.Customization options:Size (length/wall thickness), surface finish (HDG thickness 430-600g/㎡ customizable), packing (custom logo, carton, pallet), material composition (adapt to national standards of different countries).

2.Customization Process:Send your requirements (drawings/samples) → Get a customized quote within 24 hours → Confirm sample → Mass production (ISO9001 certified) → Direct shipping to your plant.

3.Adaptation standards:Compliant with international standards (ISO) and local regulations of 150+ countries (e.g., Russia, Australia, USA, South Africa) — no need to modify for regional use.

1. How to start an OEM order?

Send drawings or sample-Getting price-Payment-Make mold-Confirm sample-Mass production-Payment-Delivery.

2. What is your terms of payment?

We accept TT, L/C, Trade Assurance, Credit card, Western Union etc.

3. Could you customize the packing?

The logo, carton ans pallet can be customized.

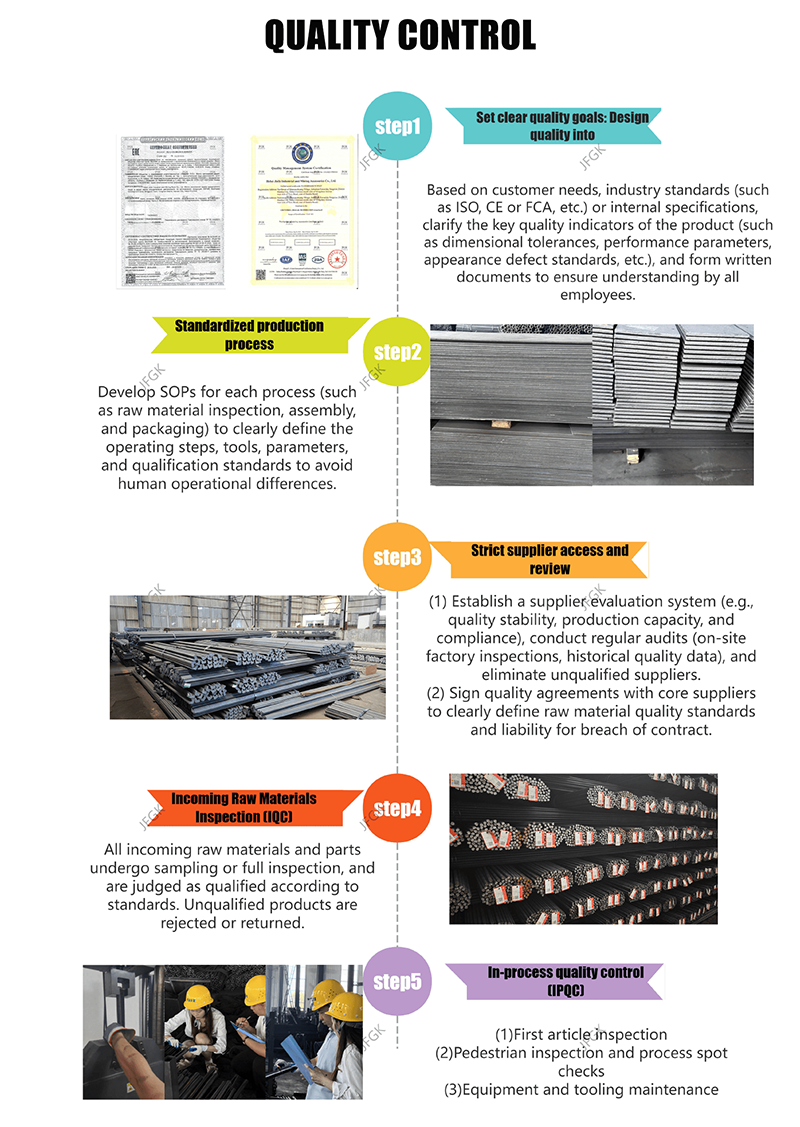

4. How do you ensure product quality?

Better control from raw material, production, processing packing, storage until to shipment.And we passed the IS09001 quality management system certification.

5.What kind of payment term you use to ship the goods?

We support FOB, CIF, CFR, DDU, DDP etc, we got very rich experience shipping goods directly to customers plant.

6.After-sales.

Quick response day and night.