Chain Link Mine Support Mesh

Product Description

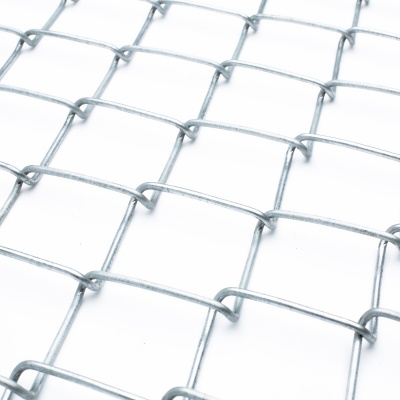

Chain Link Mine Support Mesh is the original steel wire mesh solution for coal mine and tunneling operations. Engineered with high-tensile low-carbon or galvanized steel wire, this flexible mesh delivers superior rockfall containment, structural reinforcement, and long-term corrosion resistance in harsh underground environments. Its unique interlocking design absorbs impact, prevents loose rock detachment, and creates a critical safety barrier for personnel and equipment.

Technical Specifications

| Parameter Item | Standard Specifications | Customizable Range |

| 50×50mm, 100×100mm | 50×50mm, 100×100mm | 40×40mm - 150×150mm |

| Wire Diameter | 3.0mm, 4.0mm, 5.0mm | 2.5mm - 6.0mm |

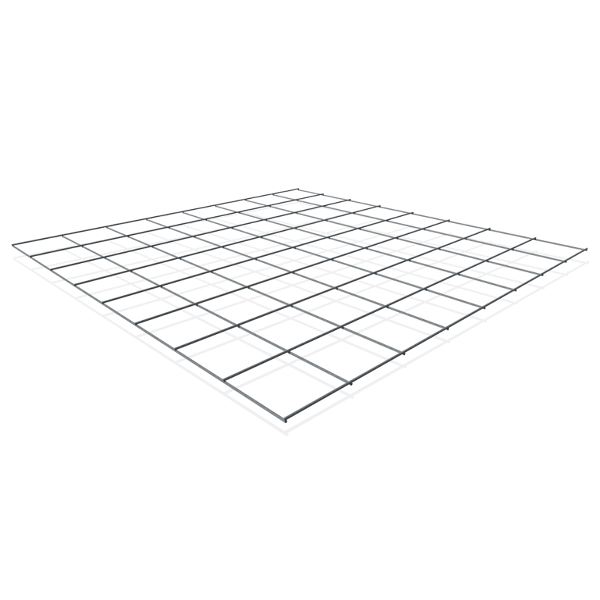

| Mesh Panel Width | 1.0m, 1.2m, 1.5m | 0.8m - 2.4m |

| Roll Length | 10m, 20m, 30m | 5m - 50m |

| Surface Treatment | Electro-galvanized, Hot-dip galvanized, PVC coated | Customizable upon request |

Key Features

1. High-Strength Load-Bearing Structure

Made of high-quality low-carbon steel wire with a tensile strength of over 550 MPa.

Unique rhombic mesh design ensures uniform force distribution.

Mesh nodes are joined using resistance welding, with weld strength no less than 95% of the raw material strength.

Standard specifications can withstand longitudinal tensile force ≥ 50 kN/m and transverse tensile force ≥ 30 kN/m.

2. Excellent Corrosion Resistance

Available with galvanized, PVC coating, or powder coating treatment.

Galvanized layer thickness ≥ 60 μm, with salt spray test corrosion resistance exceeding 500 hours.

Suitable for harsh environments such as humid and acidic/alkaline conditions in mines.

Service life of 8-15 years, significantly reducing replacement frequency.

3. Convenient and Efficient Installation

Flexible mesh design adapts to irregular rock surfaces.

Available in standard rolls (usually 10-30 meters/roll) for easy transportation and on-site deployment.

Can be quickly installed with support systems such as anchor bolts and steel reinforcement beams.

Supports customized sizes to reduce on-site cutting waste.

4. Multifunctional Protective Applications

Effectively prevents rock spalling and falling debris.

Suppresses tunnel deformation and maintains the stability of the mining space.

Can be used as reinforcement for shotcrete.

Suitable for various scenarios, including temporary and permanent support.

Application Scenarios:

Support for roof and side walls of coal mine roadways

Protection of working faces in metal mining operations

Initial and permanent support for tunnel engineering projects

Slope reinforcement and geological disaster prevention

Temporary isolation and partitioning in underground engineering projects

Why choose our mining diamond mesh?

We have 15 years of experience in manufacturing mining support products, and our products have served over 200 large-scale mining projects nationwide. Our diamond mesh is produced using automated production lines, ensuring consistent performance for every product; a strict quality control system guarantees product reliability under extreme working conditions; and our professional technical team can provide customized support solutions to help you achieve the optimal balance between safety and efficiency.

Quality Assurance

Raw materials are traceable, and each batch of steel has a quality certificate.

Full-process quality control, roll-by-roll inspection.

Complies with MT/T 228.2-2005 mining support product standards.

Product qualification certificates and third-party test reports are provided.

Professional technical support and on-site installation guidance.