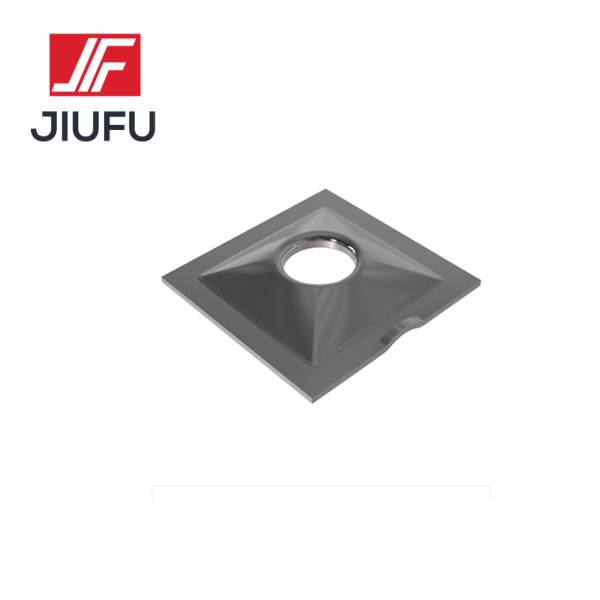

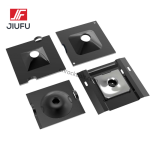

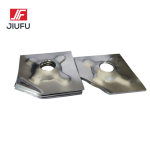

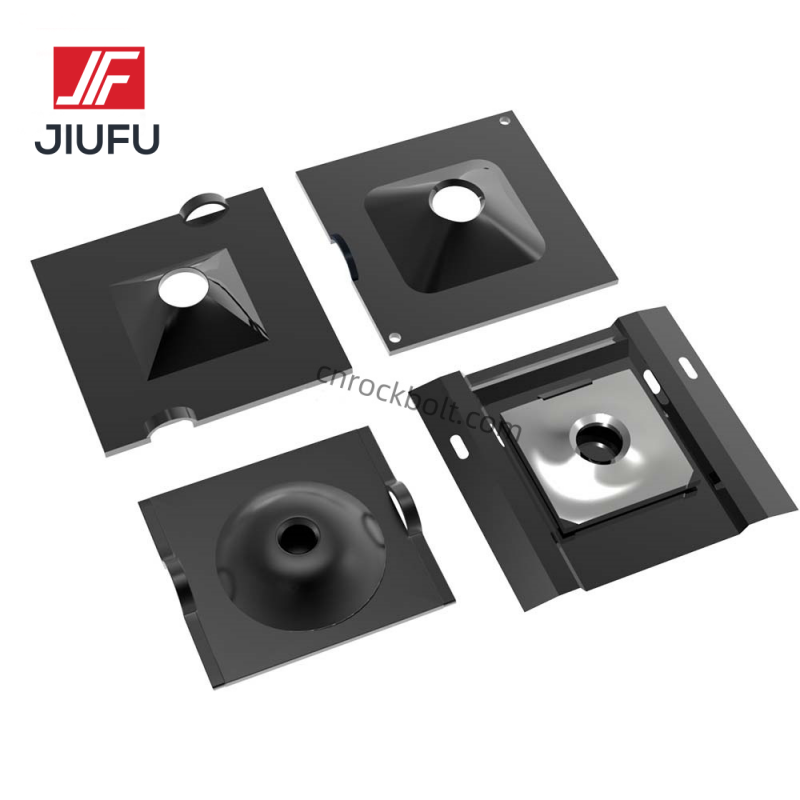

Mining Anchor Plated

Product Introduction

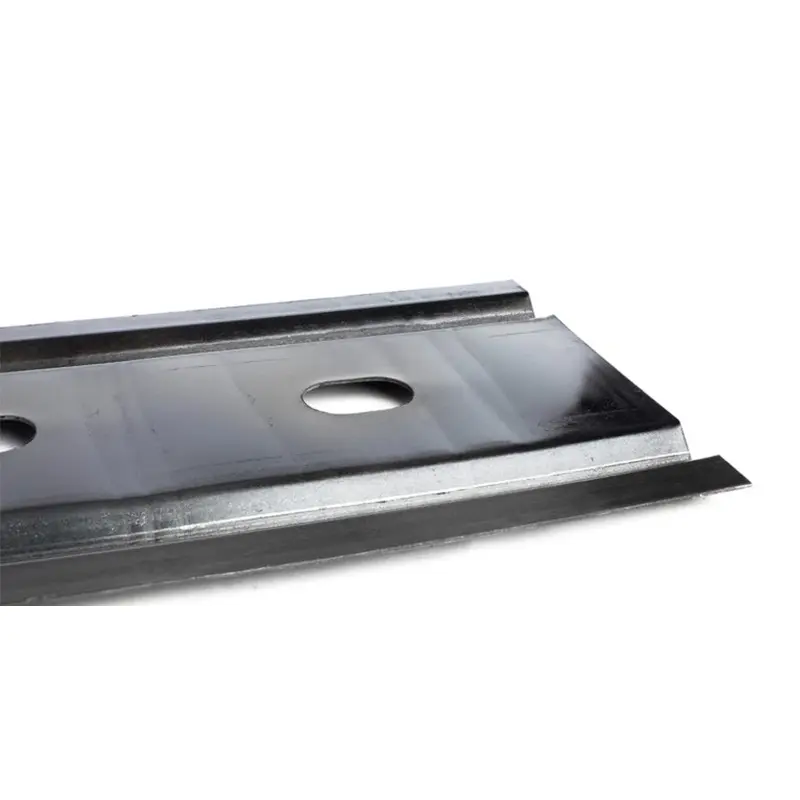

As an important part of the support system, the performance of the anchor pallet directly affects the support effect of the anchor. There are several types of pallets, the commonly used ones are round anchor pallets, square anchor pallets, butterfly anchor pallets, etc. The function of the supporting plate is to transfer the thrust generated by the nut locking torque to other components to generate the initial anchoring force. At the same time, the pressure of the tunnel roof is transferred to the anchor rod to generate working resistance, which jointly strengthens the surrounding rock and prevents the tunnel roof from breaking. Replacement Therefore, when selecting a supporting plate, the strength of the anchor plate and the anchor rod body must be matched first to avoid puncture of the anchor rod due to insufficient strength of the anchor plate. Secondly, the coordination between the anchor rod body and the anchor rod body in the supporting structure must be met to avoid uneven stress on the anchor rod body and nut due to the mismatch between the anchor rod body and the supporting plate in the supporting structure, thus affecting the support.

Product Installation

As one of the important accessories of the anchor rod, the pallet needs to be used in conjunction with the anchor rod.

So, how should the tray be installed?

Preparation work

(1)Check the model and quantity of the anchor pallet to confirm whether it meets the design requirements.

(2)Check the flatness of the installation ground to ensure that the tray can be firmly fixed on the ground.

(3)Check the length and quality of the anchor rod to confirm whether it meets the requirements.

(4)Prepare the required tools and materials, such as steel bar cutting machines, electric welders, bolts, welding rods, etc.

Demonstration steps

(1)Place the anchor pallet in the correct position and secure it to the ground with bolts.

(2)Measure the length of the anchor rod according to the design requirements, and then use a steel bar cutting machine to cut the anchor rod to the corresponding length.

(3)Insert the anchor rod into the tray, adjust the position and angle of the anchor rod, and ensure that the position and angle are correct.

(4)Use an electric welder to weld the anchor rod and the pallet to ensure stability.

(5)Repeat the above steps until all anchors are installed.

1. How to start an OEM order?

Send drawings or sample-Getting price-Payment-Make mold-Confirm sample-Mass production-Payment-Delivery.

2. What is your terms of payment?

We accept TT, L/C, Trade Assurance, Credit card, Western Union etc.

3. Could you customize the packing?

The logo, carton ans pallet can be customized.

4. How do you ensure product quality?

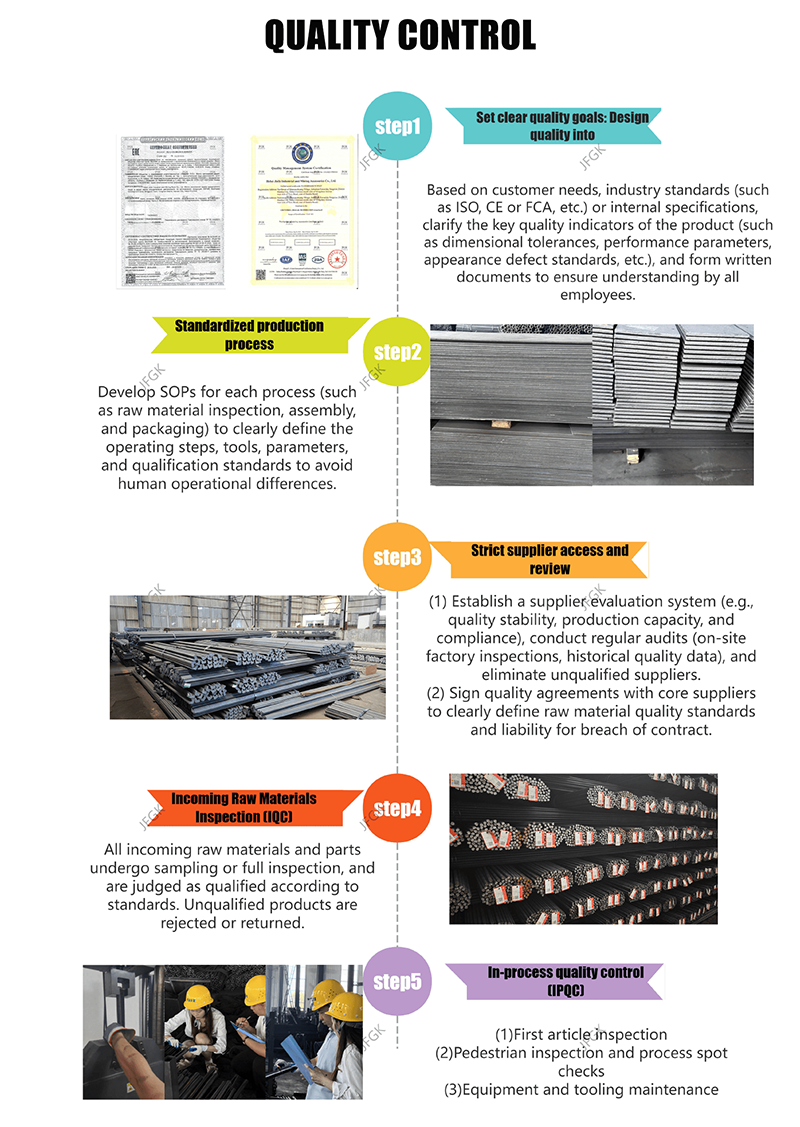

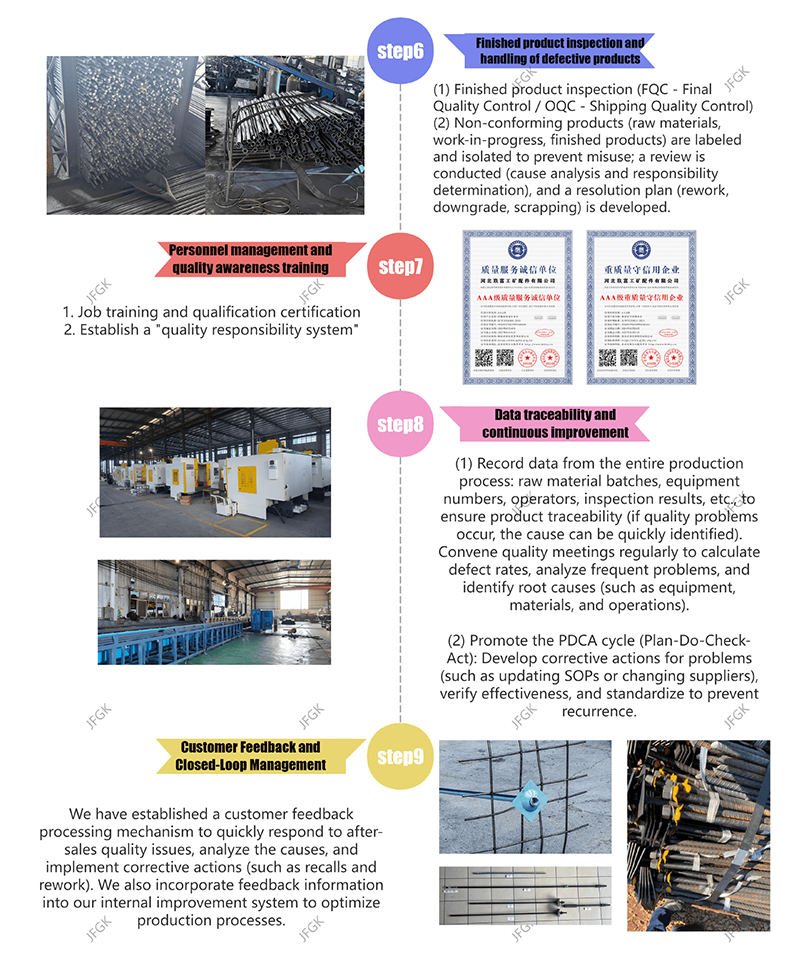

Better control from raw material, production, processing packing, storage until to shipment.And we passed the IS09001 quality management system certification.

5.What kind of payment term you use to ship the goods?

We support FOB, CIF, CFR, DDU, DDP etc, we got very rich experience shipping goods directly to customers plant.

6.After-sales.

Quick response day and night.